Various applications according to your purpose and scale

Food and beverage packaging is changing day by day to meet diversified and complicated needs.

In addition, further reliability and high functionality are required for packaging process and machinery.

Systems according to customer's purpose and scale

Basic

- Reduce initial cost

- Construct a system with minimum devices

Intermediate

- Stabilize packaging quality

- Flexible system for specification/ tool changes

- Reduce tact time

Advanced

- High-quality and flexible system

- Support predictive maintenance and traceability

- IoT Application

Less variety

(Big-lot production)

More variety

(Small-lot Production)

- - Control by using mechanical cam

- - Simple structure

- - Control by using electronic cam

- - Simple setup with iQ Monozukuri PACKAGING

- - Control by using electronic cam

- - Simple setup with iQ Monozukuri PACKAGING

- - Support for predictive maintenance and traceability

Packaging Machines

Vertical Pillow Machine

This machine feeds a packaging film roll vertically and forms a bag. After putting food in the bag, it seals and cuts the top of the bag.

System Level:

Concept Movie:

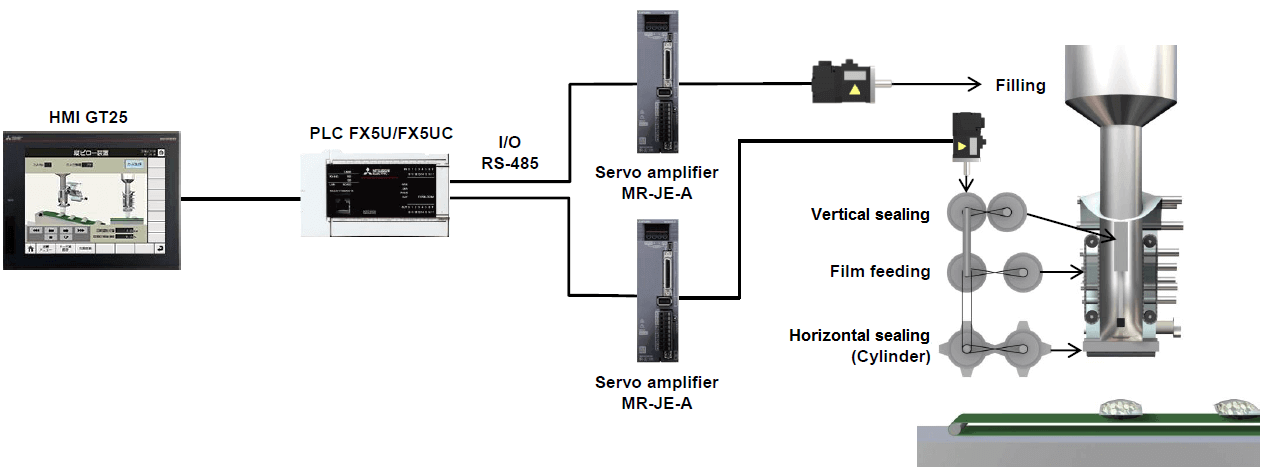

Basic System - Vertical Pillow Machine

Vertical sealing, film feeding, and horizontal sealing are mechanically interlocked and synchronized. Processes other than filling are performed by intermittent feed operation using a servo amplifier and a servo motor

System Configuration:

Equipment:

| ProcessEquipment | Filling | Film feeding/ Vertical film sealing |

Horizontal film sealing/ Film cutting |

Suggested Model |

|---|---|---|---|---|

| Drive System | Servo amplifier + Servo motor (Built-in positioning) |

Servo amplifier + Servo motor (Built-in positioning) |

MR-JE-□A |

|

| Controller | I/O or serial communication from PLC | FX5U/ FX5UC | ||

| Visualization | GT25 (Support GOT Drive function) |

|||

* Member Only Content

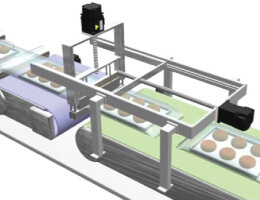

Horizontal Pillow Machine

This machine feeds a packaging film roll horizontally, wraps food supplied from the conveyor in pillow shape, and then seals and cuts the both ends.

System Level:

Concept Movie:

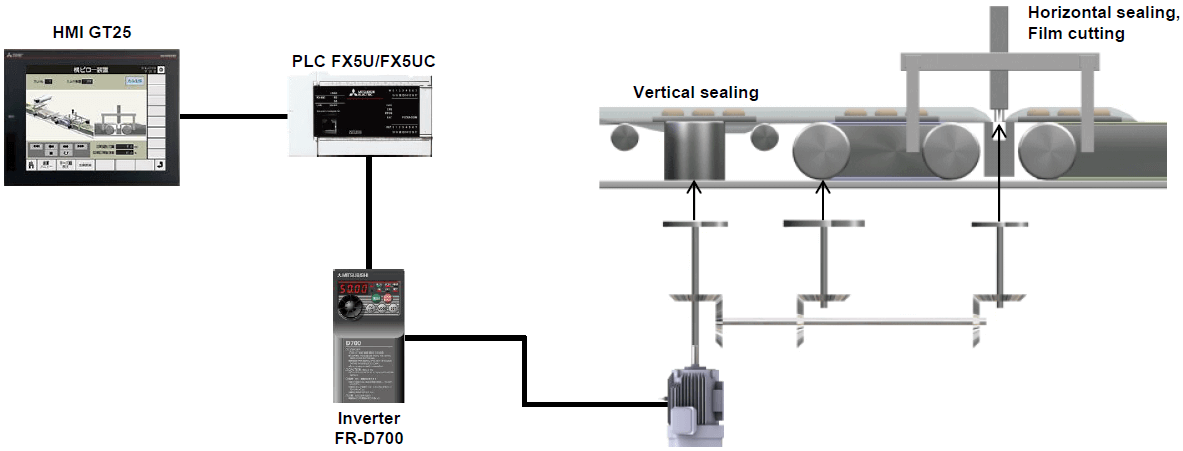

Basic System - Horizontal Pillow Machine

The rolls in each process (conveyor, vertical sealing, horizontal sealing) are mechanically interlocked and driven. The speed can be adjusted with an inverter, but the system operates at a constant speed. It is suitable for mass production of small varieties because the mechanical cam needs to be changed when the package specification is changed.

System Configuration:

Equipment:

| ProcessEquipment | Transport | Film wrapping | Film sealing | Film cutting | Suggested Model |

|---|---|---|---|---|---|

| Drive System | Inverter + Induction motor |

FR-D700 □K (Speed control) |

|||

| Controller | I/O or serial communication from PLC | FX5U/ FX5UC (Constant speed feed/ Tension control) |

|||

| Visualization | GT25 (Support GOT Drive function) |

||||

* Member Only Content

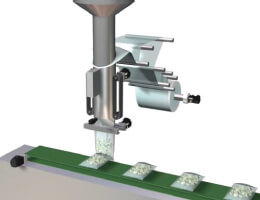

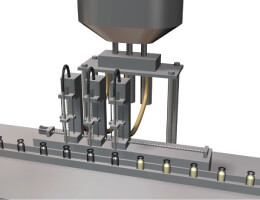

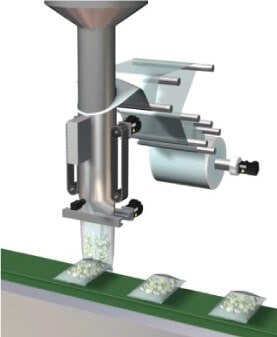

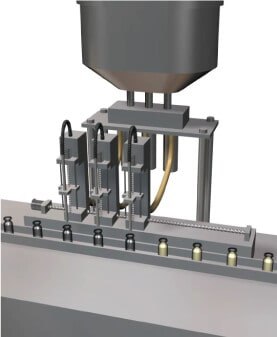

Filling Machine

Solid or liquid material is charged to the optimum amount

System Level:

Concept Movie:

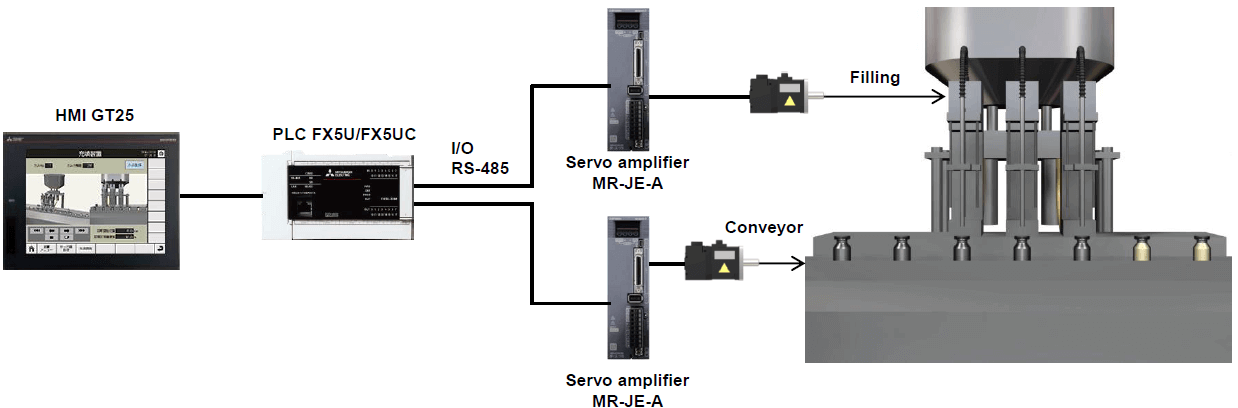

Basic System - Filling Machine

Vertical sealing, film feeding, and horizontal sealing are mechanically interlocked and synchronized. Processes other than filling are performed by intermittent feed operation using a servo amplifier and a servo motor

System Configuration:

Equipment:

| ProcessEquipment | Conveyor | Filling (rise or lift) | Filling (travel motion) | Suggested Model |

|---|---|---|---|---|

| Drive System | Servo amplifier Servo motor |

- |

MR-JE-□A (Built-in positioning) Filling: Positioning (Adjust the nozzle height to the liquid level) Conveyor: Positioning (Intermittent operation) |

|

| Controller | I/O or serial communication from PLC | - | FX5U/ FX5UC | |

| Visualization | - | GT25 (Support GOT Drive function) |

||