Data collection solution

Mitsubishi Electric FA products support data utilization

Our products help customers solve problems in various data utilization situations.

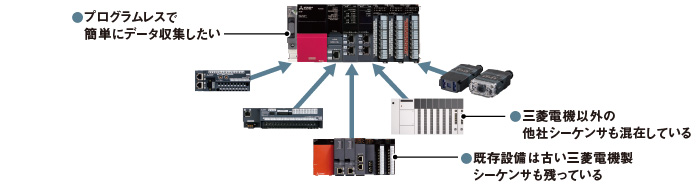

I want to easily collect data from the manufacturing site into field equipment

Product details

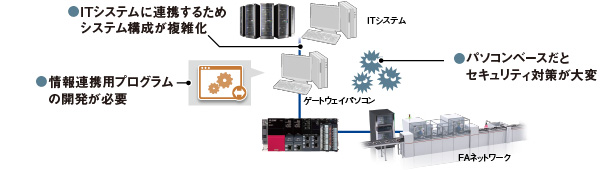

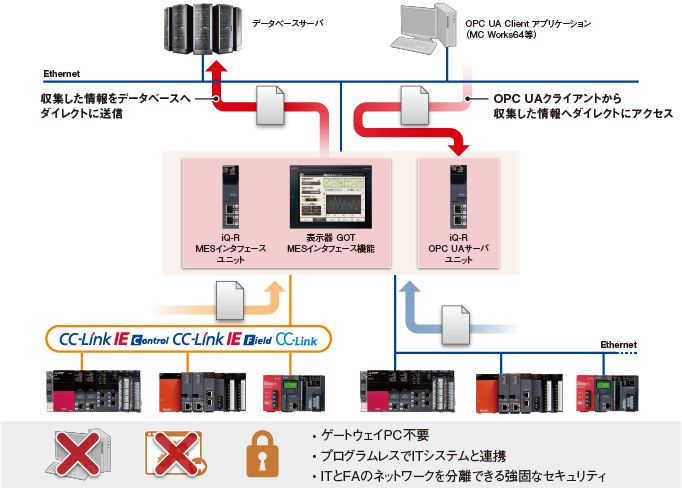

I want to use the data collected in the PLC in the IT system

Product details

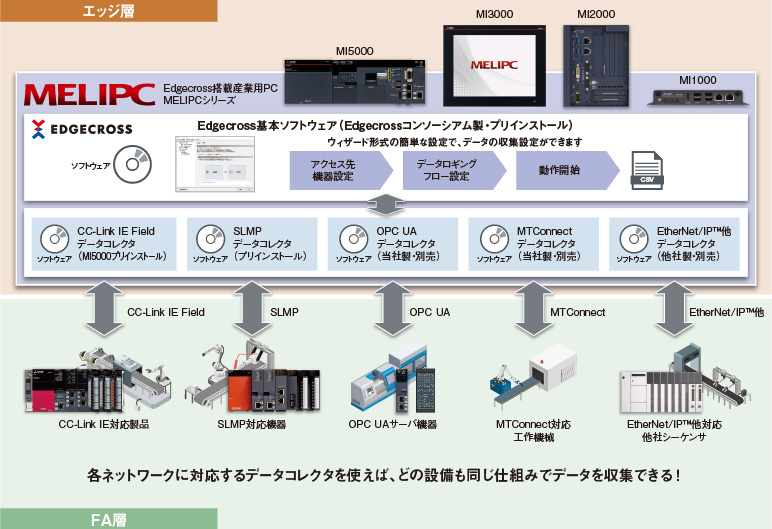

There are various devices and networks at the site, so it is difficult to connect and collect.

Product details

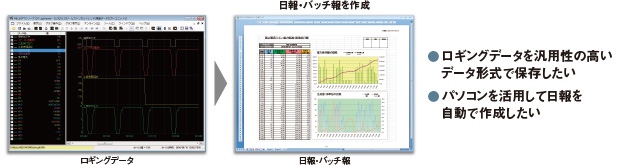

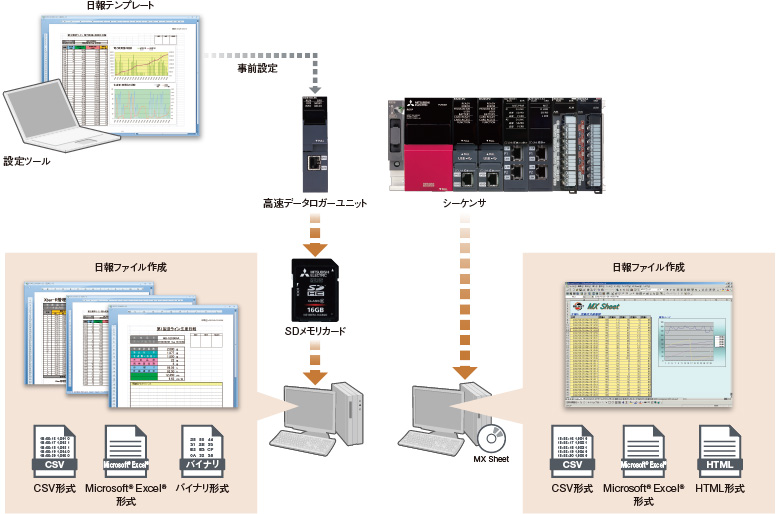

I want to collect data and put it together in a report

Product details

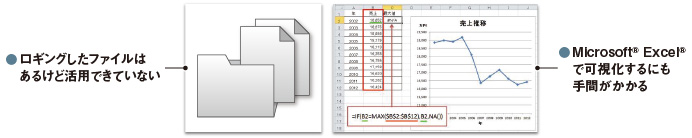

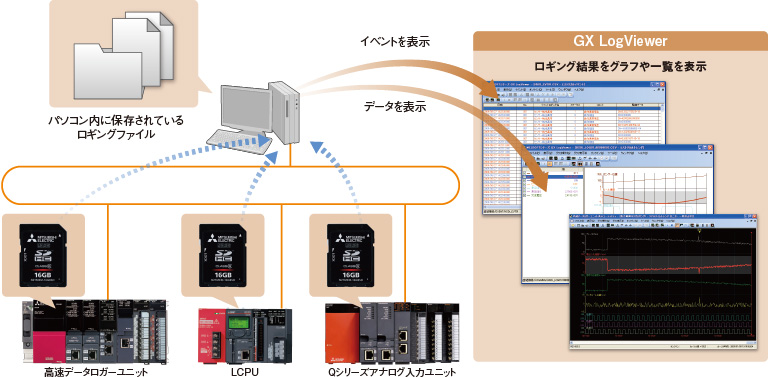

I want to easily visualize logging data

Product details

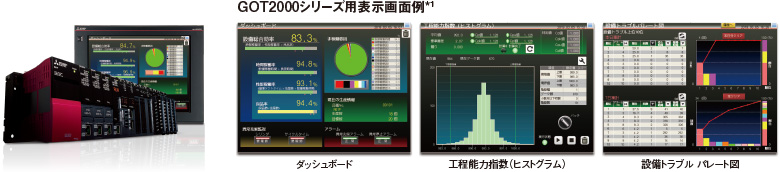

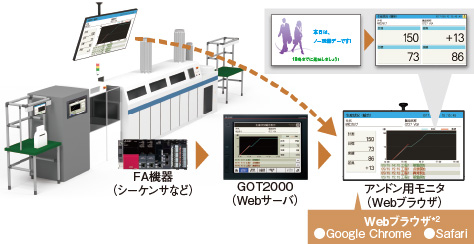

I want to confirm the collected data at the production site

Easy visualization on-site display GOT by using eF @ ctory support module

iQ Monozukuri Using Andon to easily build an Andon system

Product details

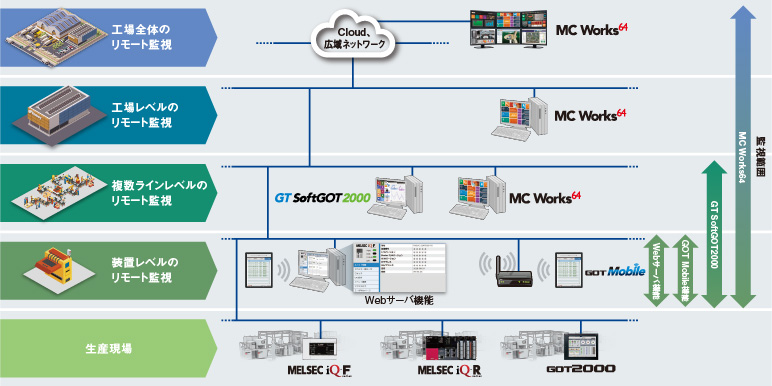

I want to check the condition of equipment on the production site from an office or a remote place

Full range of products and functions that realize remote monitoring according to the operation level

| Operation level | Realized products / functions |

|---|---|

| Detailed integrated remote monitoring from equipment level to the entire factory | MC Works64 (SCADA software) |

| Easy remote monitoring from equipment level to multiple line level | GT SoftGOT2000 (HMI software) |

| Simple remote monitoring of equipment level remote monitoring with a Web browser | GOT Mobile function (Display GOT function) Web server function (MELSEC iQ-R / iQ-F series CPU module function) |

Product details

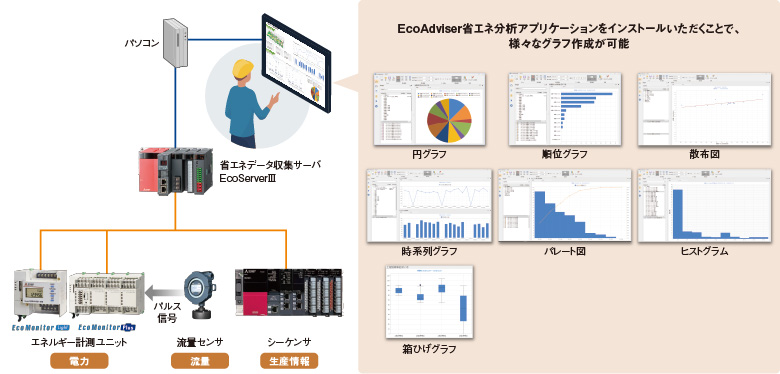

I want to perform energy-saving analysis based on the amount of electricity used and the number of products produced.

Product details

I want to easily perform analysis / diagnosis using a sophisticated algorithm on a sequencer

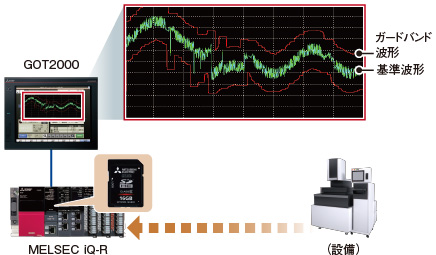

Waveform guard band monitoring

- Create a guard band waveform based on the reference waveform and monitor the waveform of input data.

- The created guard band waveform can be saved / read as CSV. It is also possible to read the guard band waveform created on a personal computer.

Benefits of introducing the eF @ ctory support module

- Since it is not necessary to create the sequence program and screen data from scratch, the introduction cost can be reduced.

- IoT function can be added only with basic settings * 1

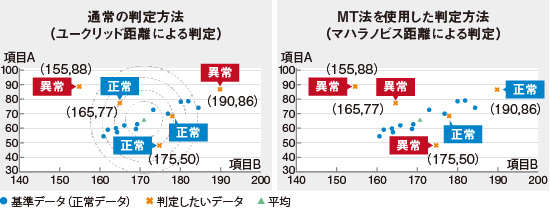

MT method simple diagnosis solution

- Multivariate analysis method for anomaly detection.

- Normality / abnormality is determined by creating a standard (unit space) from normal data and digitizing the degree of deviation (Mahalanobis distance) between the standard and measured data.

- The sequencer calculates time series data and vibration data feature quantities, and the Mahalanobis distance is monitored by the MT method.

- Since data can be collected, visualized / analyzed, and diagnosed directly with the sequencer and GOT, the necessary equipment is easily available and maintainable, and it is easy to install on site.

Product details

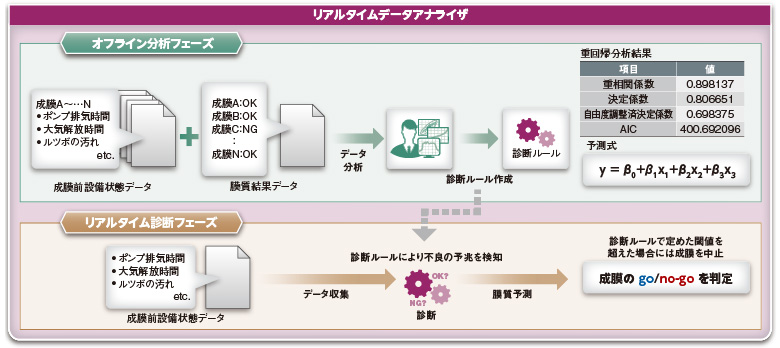

Want to improve quality and perform predictive maintenance by analyzing various data at the production site.

- A multiple regression analysis is performed and a prediction formula for predicting the film quality result is derived from the equipment state data.

- By predicting the film quality result in real time, the occurrence of defective film quality products is suppressed.

Product details

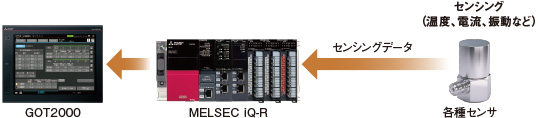

Predicting maintenance of equipment by diagnosing vibration data of rotating machinery

Support module vibration analysis

The eF @ ctory support module is a sample project for MELSEC iQ-R series and GOT2000 series. Since general-purpose vibration analysis such as frequency analysis (FFT) and monitoring of vibration intensity for each frequency band is possible, it can be used for vibration analysis of various equipment.

Equipment such as glass cutting equipment, grinders, etc., where vibration is expected to change during abnormal times

Rotating machine vibration diagnosis

We provide packaged projects for MELSEC iQ-R series and GOT2000 series whose operation is guaranteed by our company.

Simply connect the required equipment, install the package program and screen data, and start general-purpose vibration analysis and rotary machine vibration diagnosis.

You can even diagnose what is wrong with equipment that has a rotating mechanism.

Equipment with rotating machines such as motors, blowers, compressors, pumps, speed-up / down gears, conveyors, converting machines (equipment such as press machines that generate impact vibrations or self-propelled equipment such as AGVs are not included)

Contact Us

Contact Us Call Center

Call Center