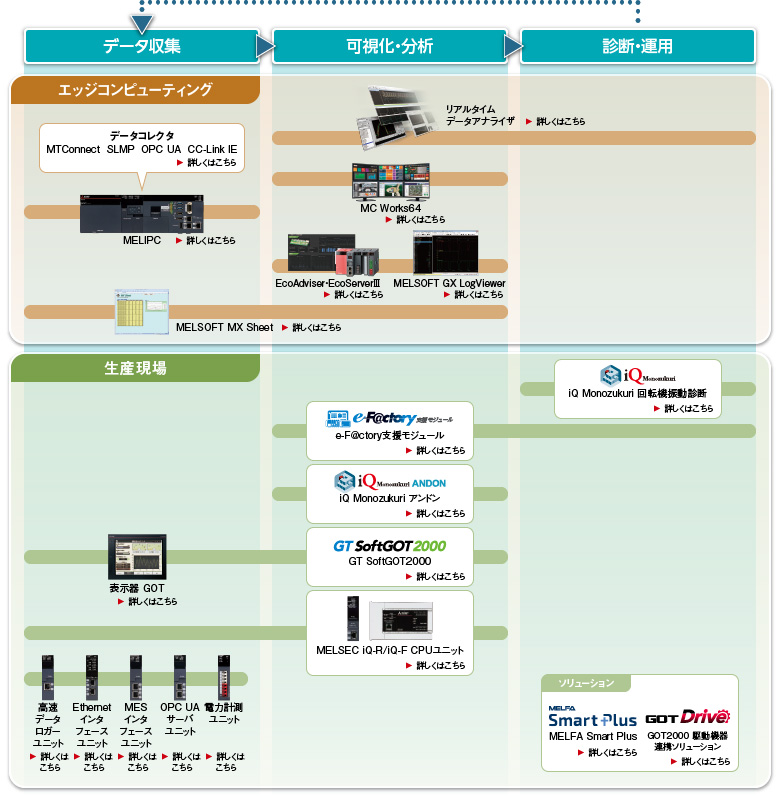

Solutions

Data collection / analysis solution

Mitsubishi Electric FA product lineup

Real-time data analyzer

Data analysis / diagnosis software that easily realizes quality improvement and predictive maintenance at the production site. We realize offline analysis of production site data and real-time diagnosis with one product. Using AI technology and various statistical methods, we will utilize the data at the production site and contribute to improving the corporate value of our customers.

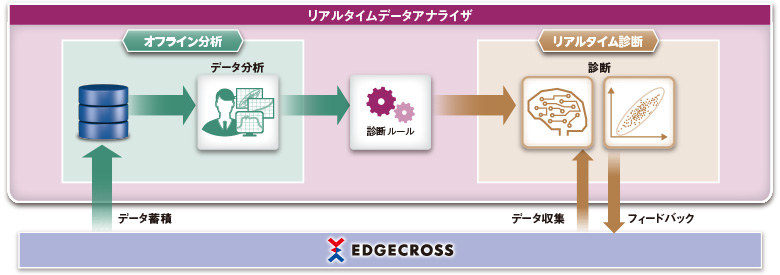

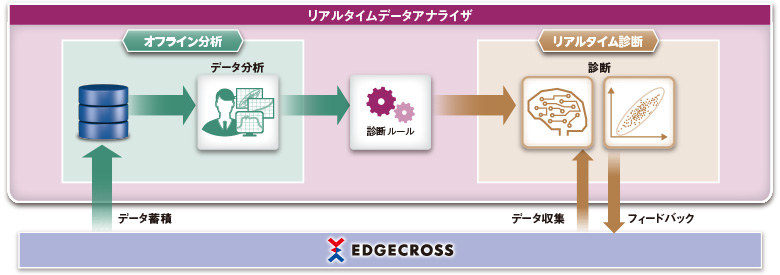

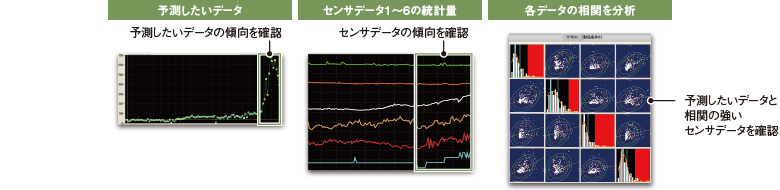

Improving manufacturing in real time with both wheels of offline analysis and real-time diagnosis

Data utilization in FA can be divided into an offline data analysis phase and a real-time collected data diagnosis phase. Real-time data analyzer can realize them with one software and can directly connect to the production site. Therefore, it is possible to directly apply the data analysis result to the diagnosis without the need to build a separate diagnosis system.

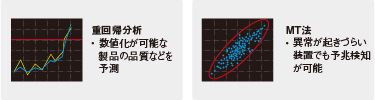

Equipped with AI technology and many statistical analysis methods

AI technology utilizing the FA manufacturer's knowledge and numerous statistical analysis methods support customers' data utilization.

AI technology (similar waveform recognition)

Many statistical analysis methods

Others, SPC, guard band, etc.

Easy data analysis without programming

No programming is required, and a wealth of GUI functions enable easy analysis with a mouse.

Contact Us

Contact Us Call Center

Call Center