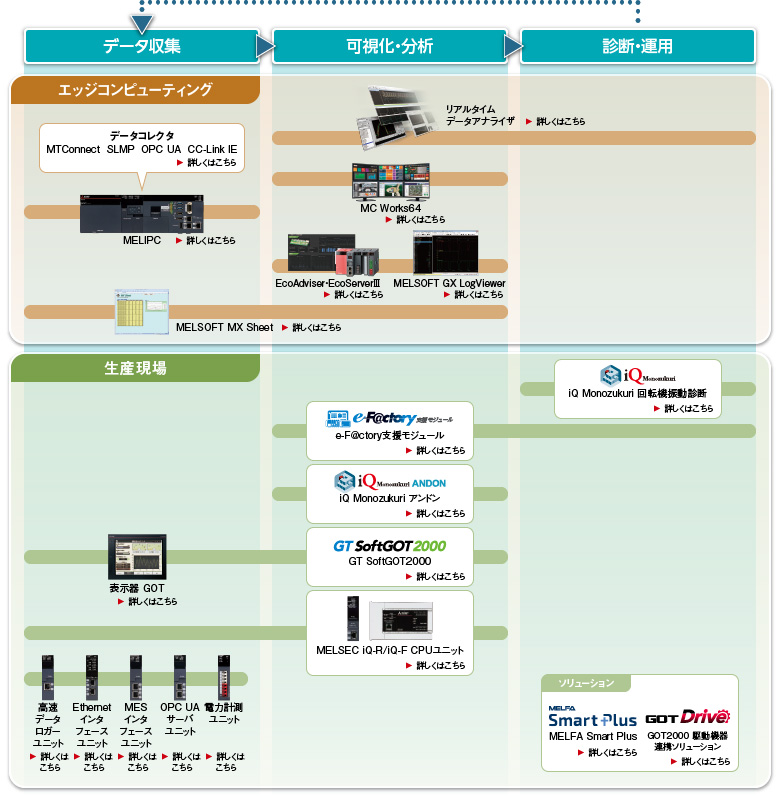

Data collection / analysis solution

Mitsubishi Electric FA product lineup

MELSEC iQ-R series / iQ-F series CPU module

With the data logging function installed in the CPU module, the data specified by the dedicated setting tool can be saved in the SD memory card installed in the CPU module. Utilizing the saved CSV file, you can create various materials such as "daily report", "form preparation", "report", etc. according to the purpose, and it is effective for data analysis and traceability at startup.

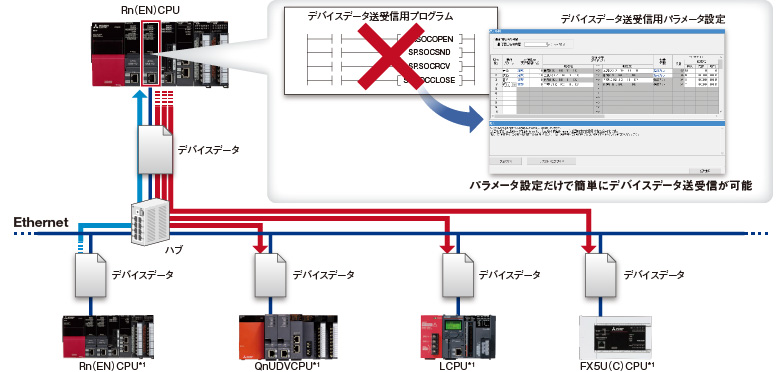

Device data transfer without program by simple CPU communication function

Device data such as production data can be transferred without a program simply by making a simple setting using GX Works3. In addition to communication between MELSEC iQ-R series, it is possible to easily communicate with existing systems using iQ-F series, Q series, and L series.

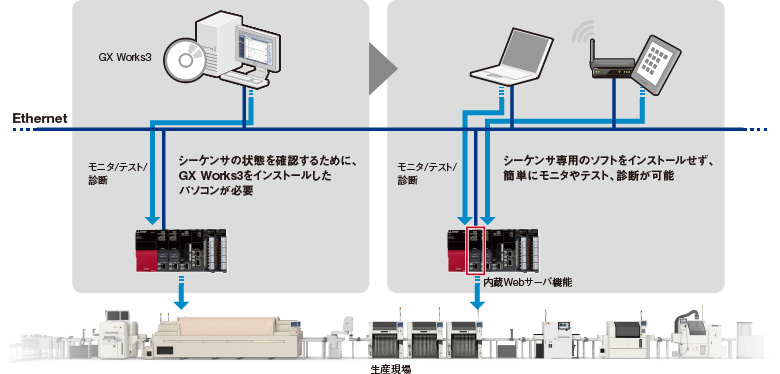

Easy primary diagnosis by utilizing the Web server function with built-in CPU

You can easily perform CPU diagnosis and device batch monitoring via a web browser on a computer or tablet. It is not necessary to prepare a personal computer on which the engineering software GX Works3 is installed, which facilitates the primary diagnosis when a trouble occurs.

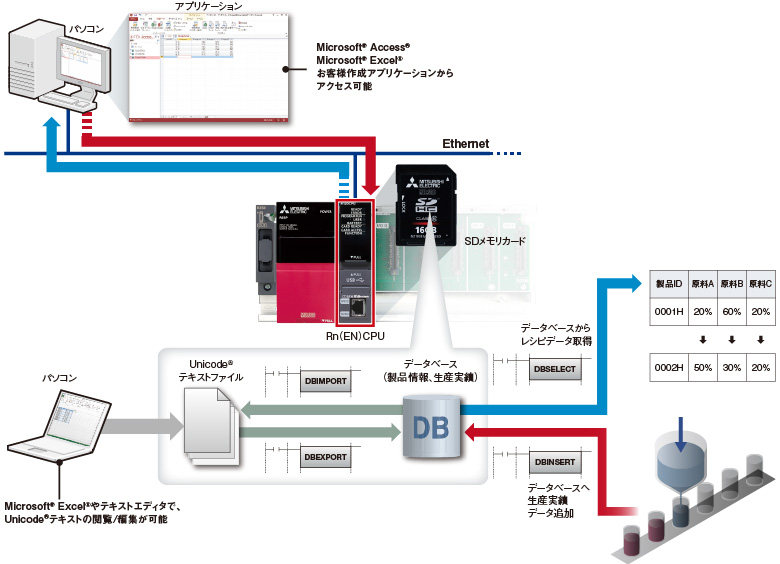

Data management with database function built in CPU

You can manage recipe data and production record data that were previously managed on a personal computer using the programmable controller built-in database. The database is created on the SD memory card, and it is possible to easily add / update / search / delete data using dedicated instructions. In addition, the database can be imported / exported in Unicode® text file format, easily linked with spreadsheet software, and accessed directly from an application on a PC via a network. It is especially effective to use it for changing recipe data and managing production results in food and beverage production lines that perform multi-product production.

Contact Us

Contact Us Call Center

Call Center