Energy saving solution

We propose equipment and systems according to the equipment status and scale.

Energy consumption is monitored by the energy measurement unit !

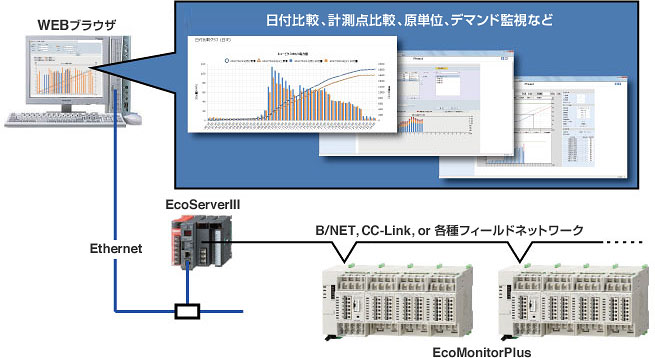

Energy information is monitored by the "Energy measurement unit EcoMonitorPlus", which makes it easy to build and expand the system according to the scale. By connecting to "Energy Saving Data Collection Server EcoServerⅢ", you can manage multiple EcoMonitorPlus at once. Preventive maintenance of equipment is realized by remotely monitoring the operating status of equipment and lines on a web browser.

Product Info

Energy saving data collection server EcoServerIII

- Realization of graphing of measurement data on a web browser.

- Real-time measurement and confirmation of energy usage is possible within the same network.

- The graph required for energy saving management is installed as standard. Easy to set up.

- Basic unit management can be realized in cooperation with the production information of Mitsubishi PLC.

Energy measurement unit EcoMonitorPlus

- The energy-saving system can be expanded in stages.

- Easily collect measurement data by creating forms and graphs.

- Preventive maintenance of equipment is realized by monitoring leakage current, load current, temperature, vibration, etc.

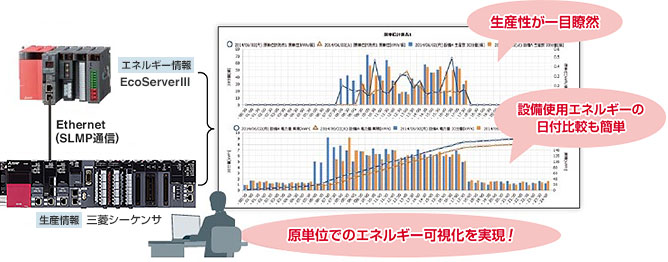

Realize unit energy consumption management by linking production information with a PLC !

Energy information of production facilities and utility equipment is visualized by "Energy Saving Data Collection Server EcoServer III". In addition, by linking with the Mitsubishi programmable controller , "basic unit * management" is realized based on the production information of the Mitsubishi programmable controller and the energy information of EcoServer III . This will lead to detailed improvement activities for each facility.

Product Info

Energy saving data collection server EcoServerIII

- Realization of graphing of measurement data on a web browser.

- Real-time measurement and confirmation of energy usage is possible within the same network.

- The graph required for energy saving management is installed as standard. Easy to set up.

- Basic unit management can be realized in cooperation with the production information of Mitsubishi PLC.

MELSEC iQ-R

- ealized the construction of automation system with high productivity and stable quality. Solving from three perspectives of "TCO reduction", "reliability" and "inheritance". It is the core of the next-generation total solution advocated by Mitsubishi Electric.

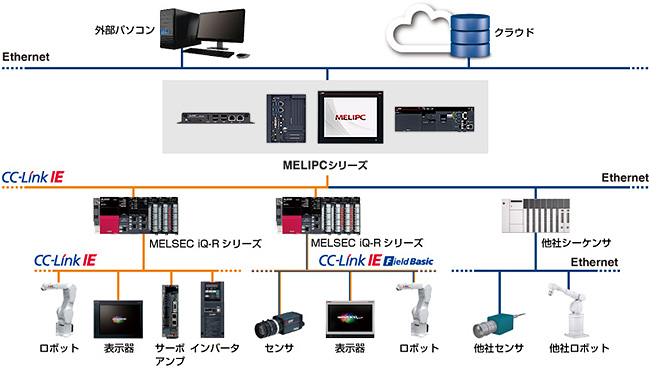

When the facilities and equipment on the production site are multi-vendor!

Edgecross * compatible "industrial PC MELIPC" enables data collection from various facilities in the factory. Realizes visualization of all energy information.

Product Info

Industrial PC MELIPC

We respond to various needs such as real-time control at the production site, preventive maintenance and quality improvement, and contribute to the improvement of the production site by utilizing data.

Open platform EDGECROSS

Contact Us

Contact Us Call Center

Call Center