Energy saving solution

By replacing existing facilities and equipment with high-efficiency facilities and equipment, the energy saving effect is improved.

FREQROL-F800 / F700PJ, IPM motor MM-EFS

With the variable speed control of a general-purpose motor, it is used as an energy-saving device for fans and pumps. Now, the FR-F800 series of fan / pump inverters, which can drive even more efficient IPM motors than general-purpose motors, and the compact FR-F700PJ series have appeared. In addition, for the IPM motor, we have added a lineup of the "MM-EFS series" that pursues energy saving. Equipped with RS-485 terminal as standard, it can be connected to various networks by communication option.

- Realization of energy saving by rotation speed control

- IPM motors are so efficient and energy-saving

- Realization of energy saving by optimal excitation control (general-purpose motor)

General-purpose inverter FREQROL-A701

Introducing the FR-A701 series, which is equipped with a power regeneration function in the acclaimed Mitsubishi high-performance general-purpose inverter "FR-A700 series" and has achieved a large braking capacity. Since the power regeneration function is built into the inverter, the complicated and cumbersome wiring work required up to now can be reduced, and space can be saved.

Since the amount of power regenerated can be checked on the power regeneration monitor, the energy saving effect is also obvious.

It contributes to energy saving in machinery such as elevators, cranes, centrifuges, and winders that generate regenerative torque.

- Energy saving by power regeneration function

- Realization of wiring and space saving

- Demonstrate great braking ability

- Follows the high performance and high performance of A700

Premium efficiency motor SF-PR series

The "Super Line Premium Series SF-PR" energy-saving motor has achieved the industry's highest level of efficiency and improved inverter drive characteristics.

Since the mounting dimensions (frame number) are compatible with our standard efficiency motor SF-JR series, replacement is smooth. In addition, the control equipment that is almost the same as the SF-JR series can be used because of the design considering the combination with our control equipment.

In 2014, we received the Japan Machinery Federation's "Excellent Energy Saving Equipment Award and Chairman's Award".

- Energy saving for Top Runner Standard (IE3)

- Allows constant torque operation in the low speed range in combination with an inverter

- Compatible mounting dimensions

- Combination with control equipment

- One unit supports Japan and the United States

CNC spindle motor SJ-D series

The CNC spindle motor "SJ" that maximizes motor performance by enhancing "energy saving" and "resource saving", as well as "safety" and "reliability" in order to respond to a society where the demand for environmental measures is increasing -D series "is born. Aiming for a design that further enhances the reliability of the product, we have worked to combine functions and design.

- High efficiency (energy saving)

- high speed

- Light weight / low vibration

- Improved reliability

Super high efficiency oil-filled transformer EX-β series

A lineup of "Ex-β series" super high efficiency oil-filled transformers based on original technological innovation. By adopting magnetic domain control electromagnetic steel strips and optimally designing the windings, we have achieved energy-saving performance that exceeds that of the top runner transformer "R series".

- Low loss design that achieves high efficiency even in the high load factor range

- Improves maintainability and seismic performance *

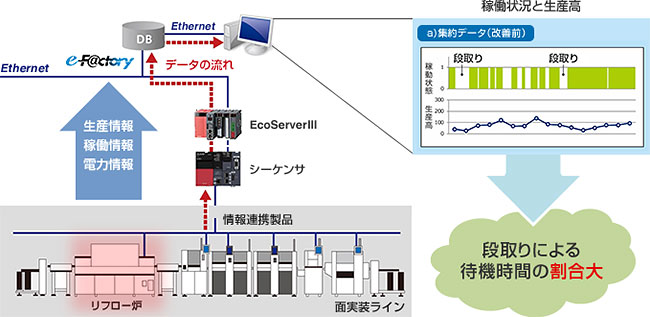

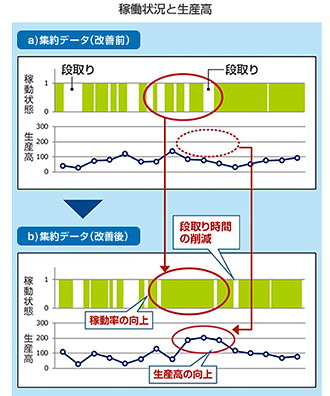

Elucidate bottlenecks in the production line and implement improvement measures.

Example of improvement: Reviewing the standby power consumption of reflow equipment

As a result of analyzing the power consumption of each facility with EcoAdviser on the production line, the facility that accounts for about 60% of the power consumption of the entire production line was found to be a "reflow furnace".

This equipment consumes electric power even during standby because of heating, regardless of operation / standby, and the electric power for the setup time wasted energy.

- Operation management system aggregates and analyzes the operating status of each facility in the line

- Visualize the waste of electricity by measuring the amount of electricity used for each facility and analyzing the correlation with the facility operating status

- Optimized setup time by streamlining and improving setup

Contact Us

Contact Us Call Center

Call Center