Equipment design efficiency solution

At the time of maintenance, I would like to check the device's design drawing and wiring diagram on site ...

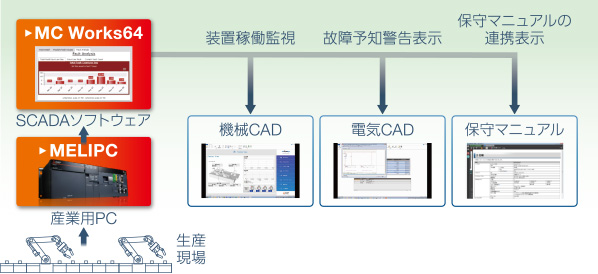

The operation information of the production line is collected by "Industrial PC MELIPC" and can be visualized in real time by "SCADA software MC Works64".

MC Works64 links with various design data such as manuals, and MC Works64 can immediately access electrical CAD drawings and maintenance manuals. In addition, since the tact time of the production line is constantly monitored by MC Works64, it is possible to diagnose the difference from the pre-designed tact time and use the SCADA software MC Works64, which can link with various design data of the problem area, The location can be easily identified.

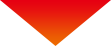

Failure diagnosis and preventive maintenance using MC Works64 and electric CAD

Downtime can be shortened by the recovery procedure from the error location and automatic display of the relevant drawing. By double-clicking the error location displayed on MC Works64, the corresponding board CAD drawing is automatically opened, and you can easily check the wiring of the error location on the screen.

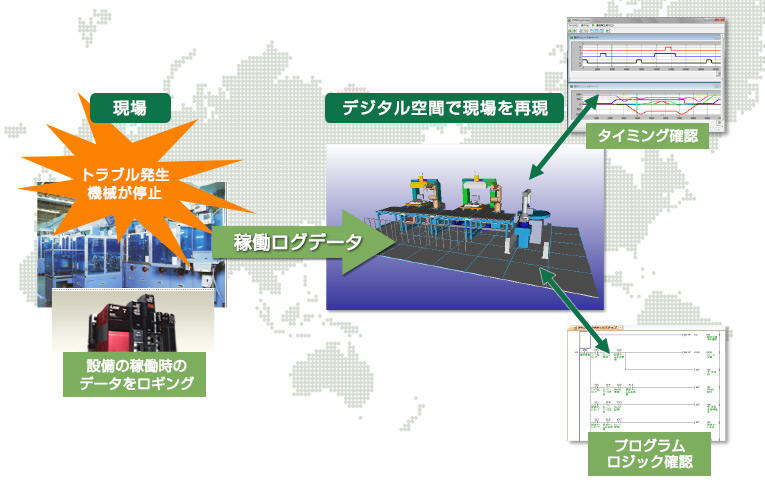

Quick troubleshooting by reproducing the equipment on site using operation data

By logging the data when the equipment is in operation using our sequencer (iQ-R, Q series) or logging unit, it is possible to reproduce the situation where the machine stopped due to a trouble on the 3D simulator of each company. I can do it.

The cause of trouble can be analyzed by checking the timing chart and the state of each signal of the program logic.

Click here for details on MELSEC programmable controllers (iQ-R, Q series)

Click here for details on the high-speed data logger unit

Partner solution introduction

Mitsubishi Electric is collaborating with many partner manufacturers to propose optimal solutions to customers. Find partner solutions here.

eF @ ctory Alliance

Contact Us

Contact Us Call Center

Call Center