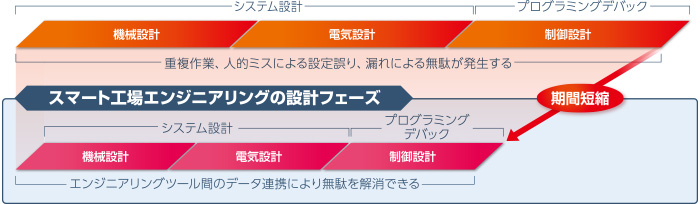

Equipment design efficiency solution

I don't want to enter the same data repeatedly for each tool ...

PLC I / O circuit diagram (signal line name and unit configuration) of electric CAD can be read into iQ Works and reflected in global label and unit configuration setting

quality robot programs are automatically generated by offline teaching with a 3D simulator .

Improving control design efficiency by diverting electrical design data

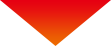

Efficient creation of electrical CAD drawings using our FA device macro data

We provide macro data of Mitsubishi FA equipment for Zuken products E3.series and EPLAN products EPLAN Electric P8. Macro data including information such as terminal name / type and device size can be downloaded and pasted on the board drawing, making it easy to create drawings. It is also possible to check the signal connection consistency, check for interference in the panel, and calculate the wiring length. Macro data has registered about 3,200 models such as low-voltage circuit breakers, sequencers, drive units, and display GOTs, and will be expanded in the future.

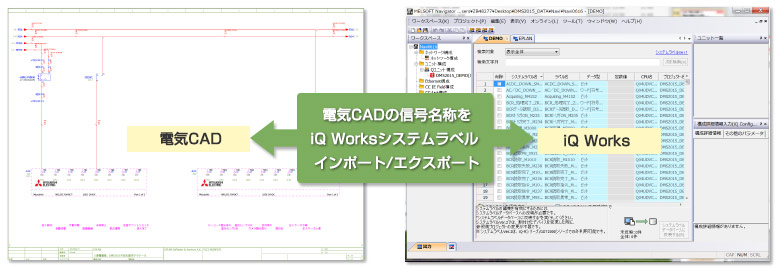

Reduction of design man-hours and quality improvement by wiring data such as electrical design wiring and signal names

It is possible to export the signal-defined name of electrical CAD to the label that is a programming variable of MELSOFT iQ-Works.

This makes it possible to improve the design efficiency and quality by diverting the signal name of electrical CAD and handling the design data between processes seamlessly.

Click here for details on MELSOFT iQ Works

Macro data for EPLAN Electric P8 Click here for EPLAN Data Portal

Click here for E3.plus macro data for Zuken E3.series

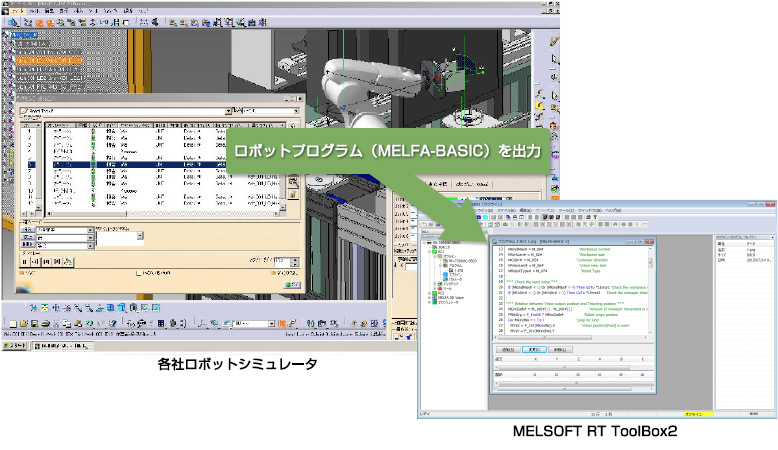

Automatic generation of robot programs by utilizing robot simulator

Since robot programs can be automatically generated from the information on each axis of robots that have been subjected to offline teaching on each company's robot simulator, the man-hours required for robot control design and verification can be greatly reduced.

Click here for details on MELSOFT RT ToolBox2

Click here for details on the industrial robot MELFA

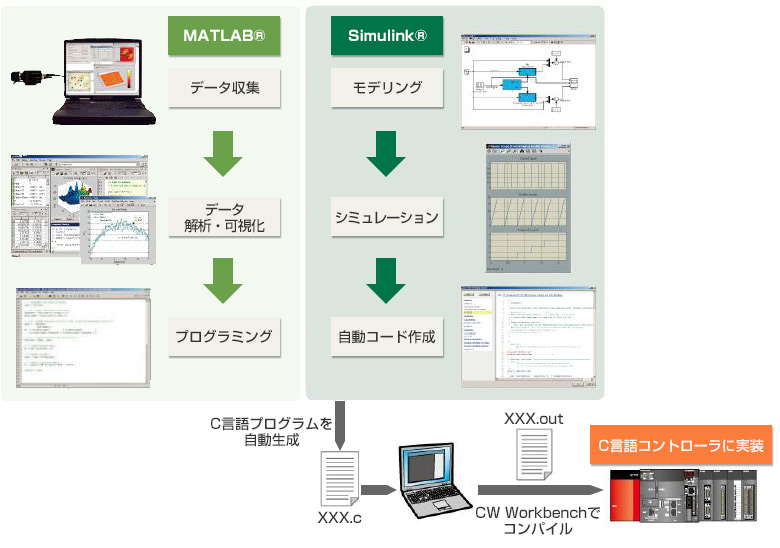

Efficient creation of control logic using model-based design tools

It is possible to automatically generate the source code for the C language controller from the calculation results (model operation) designed and verified with MATLAB (numerical calculation language as integrated development environment) and Simulink (model-based design tool, simulator).

Click here for details on embedded system solutions (C Controller)

Partner solution introduction

Mitsubishi Electric is collaborating with many partner manufacturers to propose optimal solutions to customers. Find partner solutions here.

eF @ ctory Alliance

Contact Us

Contact Us Call Center

Call Center