Embedded system solution (C controller)

Bearing deterioration diagnosis

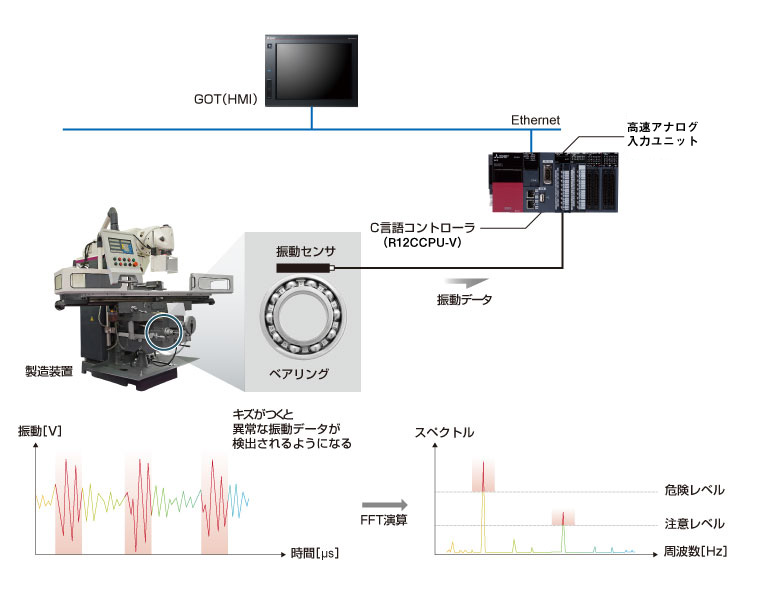

Overview

Abnormal vibration data is detected when the ball (rolling element) comes into contact with the inner or outer ring due to damage to the bearing. This data is sampled from a vibration sensor (acceleration pickup sensor) at high speed with the MELSEC iQ-R series high-speed analog-to-digital conversion unit (up to 5 μs cycle), and the collected vibration data is subjected to frequency analysis (FFT analysis) using a C language controller. . Condition-based maintenance that quantitatively grasps and predicts the deterioration state of the equipment and replaces, repairs, or updates parts before the equipment stops can be performed. It reduces the failure rate, improves equipment reliability, and reduces maintenance costs.

System configuration

Contact Us

Contact Us Call Center

Call Center