Safety solutions

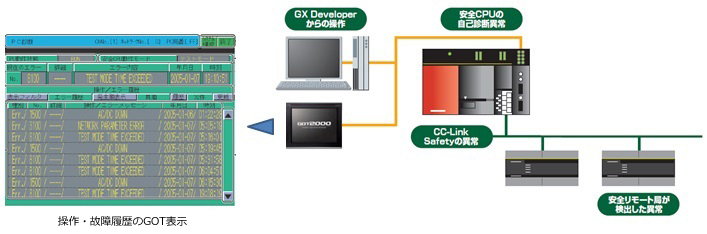

Visualization of safety control. Mitsubishi display GOT

Can be linked with the safety controller.

You can check the status of the safety controller by connecting to the CPU unit.

Using the alarm function, the operation history of the safety I / O can be checked on the GOT. The operation history can be saved as a CSV file on the memory card, or sent to the host system database using the GOT's built-in MES interface function.

Can be linked with the safety sequencer.

The data of the safety sequencer can be displayed and confirmed.

From the GOT via a network, it is possible to monitor the safety sequencer circuit * 1 , device monitor, operation / failure history, etc.

This is effective for visualizing the safety circuit and improving maintainability.

By utilizing the alarm function, the operation history of the safety I / O can be checked on the GOT.

The operation history can be saved to a memory card as a CSV file.

In addition, the operation history can be sent to the database of the host system using the MES interface function.

Easy maintenance when an error occurs.

Safety PLC circuit monitoring / operation / failure history can be displayed via the network. There is no need to bring a personal computer to the site, which is effective for improving maintainability and reducing maintenance time.

Contact Us

Contact Us Call Center

Call Center