Safety solutions

- Flexible expandability

- 8ms response performance with fast shut-off function

- Flexi Line / Flexi Link safety communication network between safety controllers

- Safety control can be easily added to existing MELSEC sequencers (CC-Link / Ethernet)

- Intuitive configuration with dedicated "setting and monitoring tool" (free of charge)

- Learn more

Safety controller MELSEC-WS series

The safety controller is a compact controller for safety control that complies with the safety standards of "EN ISO 13849-1 Category 4 PL e" and "IEC 61508 SIL 3". Ideal for safety control of small and medium-sized equipment and systems. The number of safe I / O points can be expanded up to 144 points per CPU unit according to the system configuration. In addition, a dedicated “setting / monitor tool” (free of charge) that can easily perform tasks such as setting and logic creation is also available.

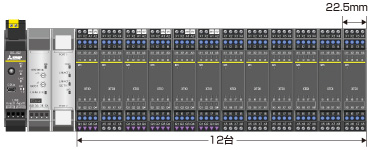

Flexible expandability

The maximum number of I / O points can be expanded to 144 points (single input). Safety input: 96 points (single output) + Safety output: 48 points (single output)

8ms response performance with fast shut-off function

The fast shut-off function, in which the safety input / output mixing unit turns off the safety output without going through the CPU, achieves a response performance of 8 ms. This function can reduce the safety distance in the safety system.

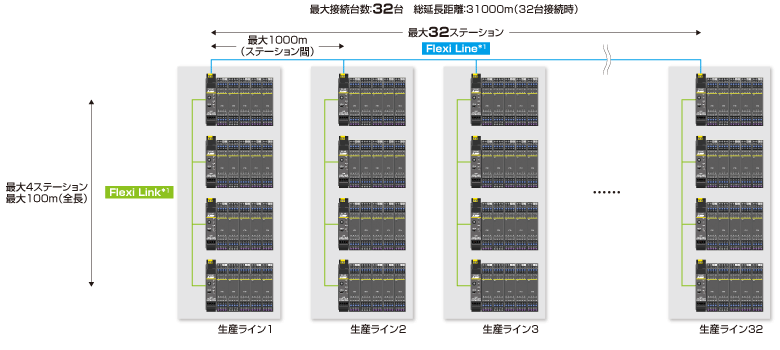

Flexi Line / Flexi Link safety communication network between safety controllers

By simply connecting the CPU units with a dedicated cable, safety communication between safety controllers can be easily realized at low cost. There is no need to add a special network unit to realize safe communication, so it can be installed and used in various production sites. In addition, the safety of the production system is improved because multiple devices can be linked.

Safety control can be easily added to existing MELSEC sequencers (CC-Link / Ethernet)

| CC-Link (WS0-GCC1) |

Ethernet (WS0-GETH) |

|

|---|---|---|

| PLC PC connection | ||

| Monitor information | ○ | ○ |

| Notification of data | ○ | ○ |

| Setting / monitor tool connection | ||

| Connection via network | – | ○ |

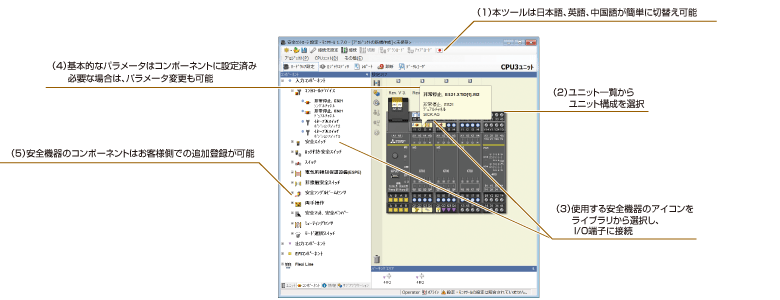

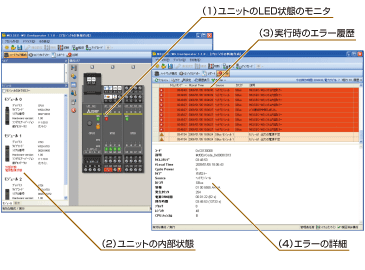

Intuitive configuration with dedicated "setting and monitoring tool" (free of charge)

The hardware configuration can be set easily and speedily using abundant components * .

Duplex settings can be made simply by dragging and dropping on the screen.

* You can download the components of each partner manufacturer's safety equipment here .

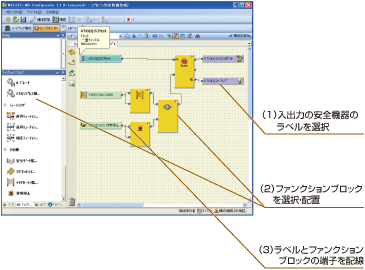

Logic creation is easy with function blocks using automatically generated labels for safety devices.

You can check the internal status of the unit and error history.

Contact Us

Contact Us Call Center

Call Center