Safety solutions

MELSEC iQ-R Series Safety CPU / Safety Remote I / O Unit

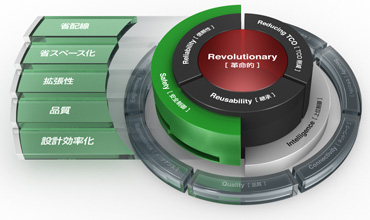

Achieves added value of the system and reduces TCO * .

To overcome the fierce market competition, we want to build an automation system with high productivity and stable production quality.

The MELSEC iQ-R series

categorizes these customer issues into seven items (productivity, program development, maintenance, quality, network, security, and compatibility),

reducing TCO , reliability, and inheritance. "From the perspective of.

The MELSEC iQ-R series is the bridge to a new era of automation , driving the <Revolutionary< progress of the

manufacturing industry.

Integration of general control and safety control

A safety CPU has been added to the MELSEC iQ-R series. The safety CPU conforms to international safety standards such as ISO 13849-1 PL e and IEC 61508 SIL 3. In addition to the general control program, a safety control program can also be executed. In the past, it was necessary to prepare a system for general control and a system for safety control separately, but if a safety CPU is used, a single system can be used to integrate general control and safety control.

Integration of general communication and safety communication networks

The safety CPU can use both general communication and safety communication in the CC-Link IE Field Network. In the past, it was necessary to lay two networks, a general communication network and a safety communication network.However, since the network to be laid is one CC-Link IE field network, wiring space can be reduced and cable The hassle can be reduced.

Centrally program general control and safety control

Using the engineering software GX Works3, the safety CPU can perform not only general control, but also programming and various setting operations on the safety control side. This can greatly reduce the hassle of having to learn the operation of various engineering software as in the past.

Contact Us

Contact Us Call Center

Call Center