Solutions

Robot solution

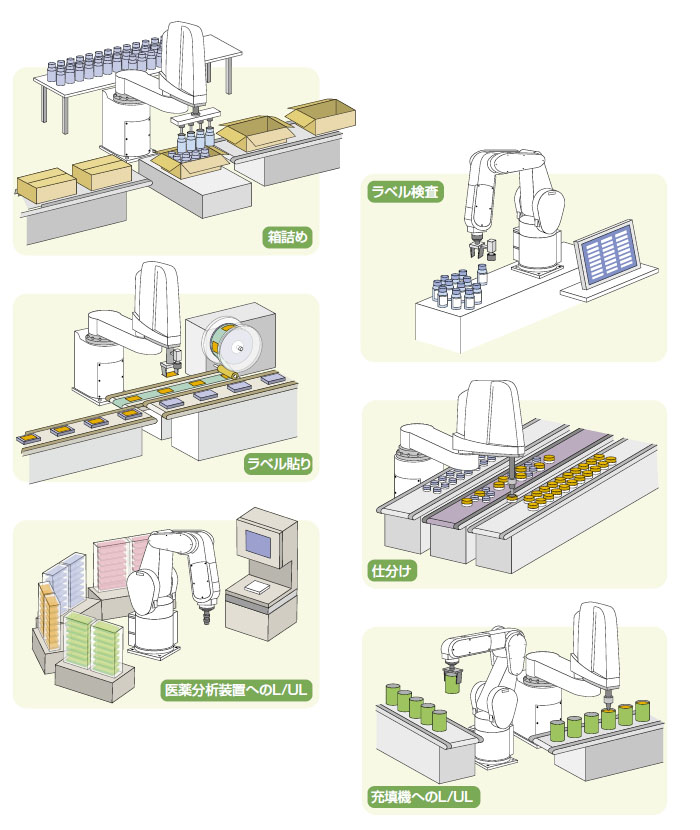

Food / pharmaceutical field

Main uses

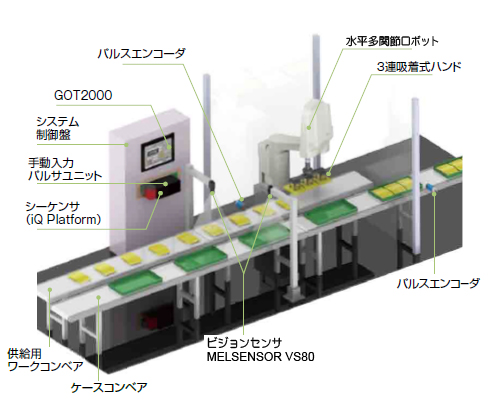

System configuration image

Robot adoption points

High-speed vision tracking by a horizontal articulated robot enables alignment work without stopping the conveyor. Simultaneous tracking for multiple conveyors is also supported.

By using the tracking function of the high-speed tracking robot, the work on the conveyor can be easily conveyed and aligned.

Alignment device is unnecessary

. A general-purpose system is constructed at low cost without a special alignment device by utilizing a vision camera.

Tact reduction The

horizontal articulated robot's joint synthesizing speed enables top-class high-speed operation and even higher precision operation.

Stable quality due to automated work

High-precision repetitive operation of the robot makes the quality and speed of each worker uniform.

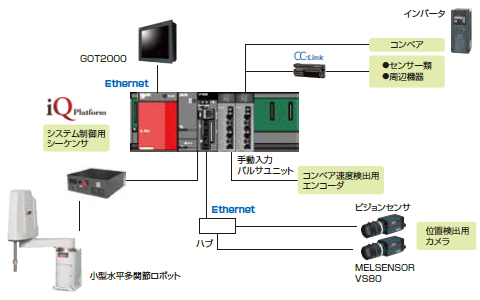

Control device configuration image

iQ Platform strengthens cooperation between PLC, GOT and robot. Optimal implementation of system operation and visualization. Achieves efficient production management with various networks and MES interfaces.

Reduction of takt time by high-speed communication between robot and PLC on iQ Platform

Easy connection with MELSENSOR

Visualization of data by linking FA devices and wiring saving by various networks

Processing / Finishing cell (video)

High speed transport solution

Robot: RH-6FH-Q x 2 units

Multi-function, high-speed, high-reliability assembly work is simply realized with a multi-function hand.

- The new tracking algorithm achieves 1.3 times the processing capacity of the conventional model.

- The robot tracking function and vision sensor allow for flexible changes in shape.

Please refer to the following for detailed specifications.

Contact Us

Contact Us Call Center

Call Center