Robot solution

Machining / Automobile parts

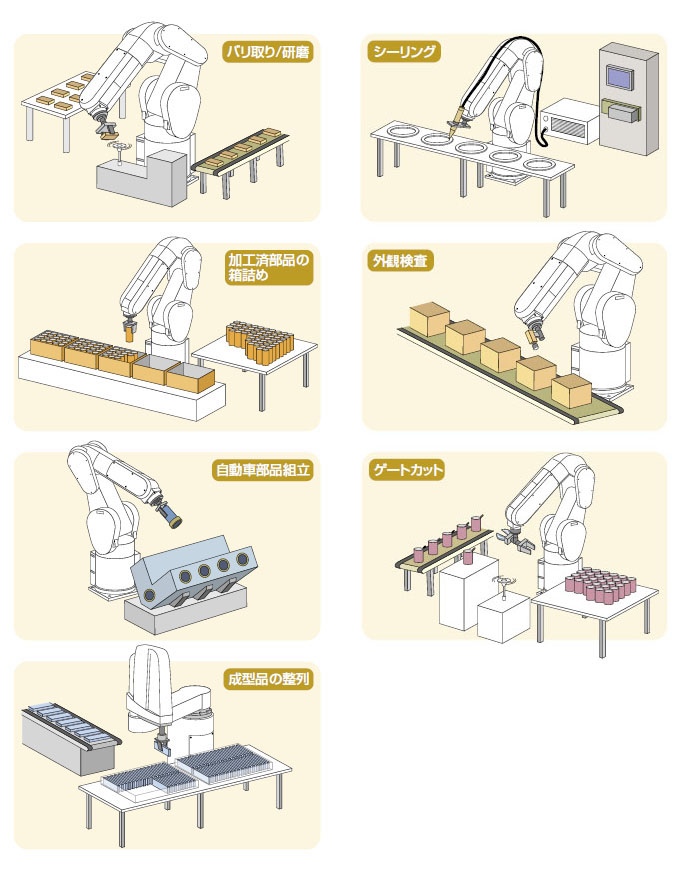

Main uses

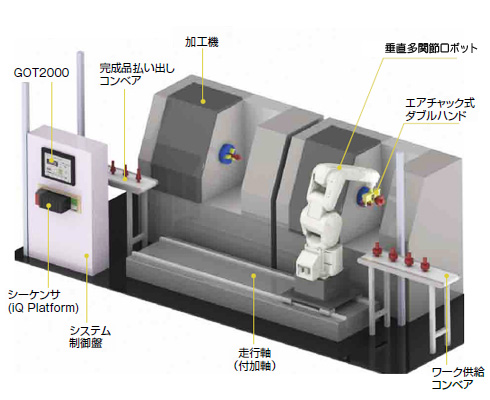

System configuration image

High-speed loading / unloading work for a processing machine by a vertical articulated robot (compatible with oil mist). By adding a traveling axis, the operating rate of the robot is improved and the installed equipment is operated efficiently.

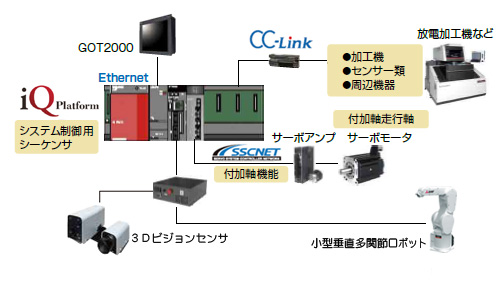

Control device configuration image

iQ Platform strengthens cooperation between PLC, GOT and robot. Optimal implementation of system operation and visualization. Achieves efficient production management with various networks and MES interfaces.

Processing / Finishing cell (video)

The 3D vision sensor makes it possible to take out bulk parts at high speed. Performs smooth surface polishing work of parts by force sensor.

- The 3D vision sensor makes it possible to take out bulk parts at high speed.

- Performs smooth surface polishing work of parts by force sensor.

Contact Us

Contact Us Call Center

Call Center