TCO reduction by strengthening cooperation

Are there any issues you want to solve at the production site?

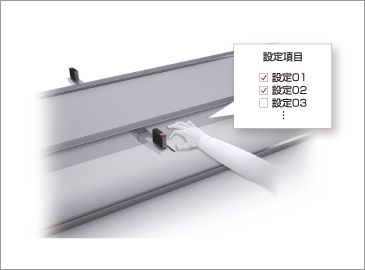

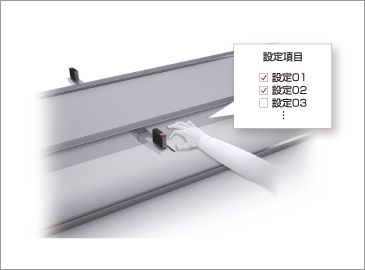

Sensor settings

The number of items to be set has increased and the complexity and sophistication of the sensors has increased the time and effort required to manage them.

There are many setting items and management is difficult

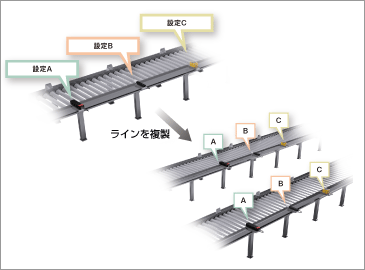

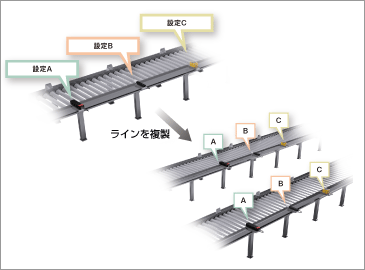

Line duplication

When reorganizing a factory, it is necessary to individually set the parameters of each sensor of an existing line, and it takes time to create a plurality of lines.

It is difficult to set each sensor parameter individually

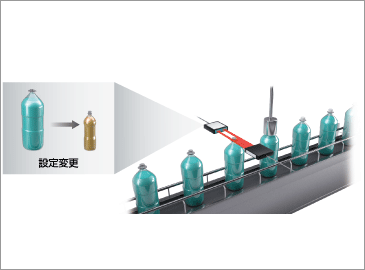

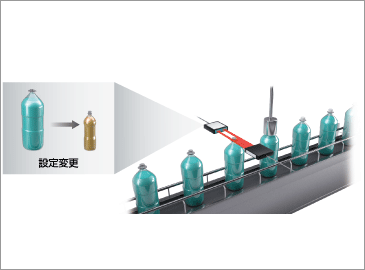

Setup change

A plurality of products are produced in one line, and it is necessary to set sensor parameters every time a product to be produced changes, which requires time for setup change.

It takes time to change settings

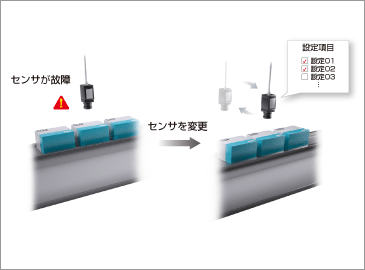

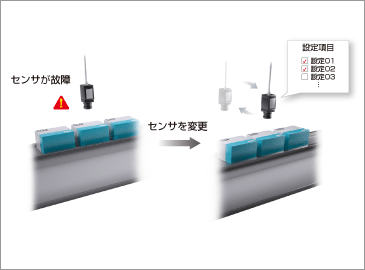

Sensor replacement

When a sensor fails, it is necessary not only to replace the sensor but also to reset the parameters of the replaced sensor, and it takes time until the system is restored.

It takes time to spread the system

IQSS solves the problems of sensor control up to now.

IQSS reduces customer's TCO by strengthening cooperation between partner sensors and sequencer / display / engineering environment

System Design

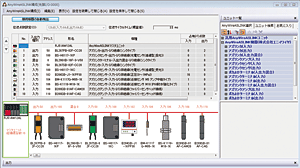

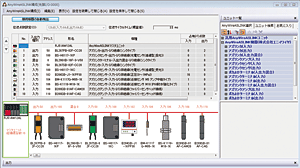

To facilitate project management, we provide a workspace tree that can manage various projects in one place, and a system configuration diagram that can describe the entire system graphically.

System configuration management

programming

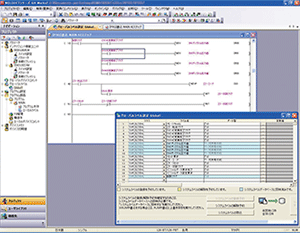

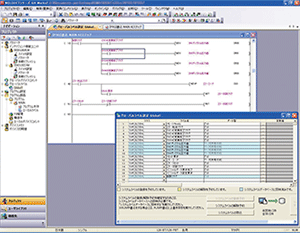

The labels used in the sequencer can also be used in displays and sensors. This eliminates the hassle of setting labels.

Libraries such as function blocks, sample ladders and GOT sample screens are also supported.

Label programming

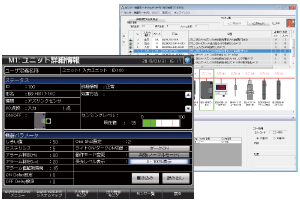

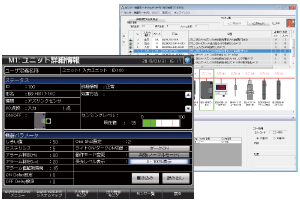

Testing and launch

In order to reduce the time required to identify the cause when a problem occurs, a function that can be monitored on a single screen based on the system configuration diagram is provided. Adjustment time for parts involving multiple devices can also be reduced.

monitoring

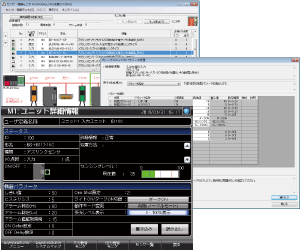

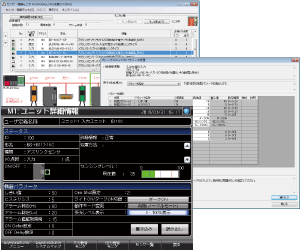

Operation and maintenance

Provides a function to read / write the settings of sequencers, displays, and sensors all at once to reduce the time and effort of backup.

Reading and writing sensor settings

Various features for reducing TCO

Development cost reduction

iQSS detects connected sensors and automatically generates a system configuration diagram.

With iQSS, sensor label name information can be easily imported by different manufacturers. You do not need to manually enter the label name. * 1

Easy programming is possible by using function blocks (FB), sample ladders and sample screens.

* 1. Not supported for Ethernet and CC-Link IE Field Network.

With iQSS, dedicated tools and manuals for each sensor can be launched from the engineering environment.

Production cost reduction

With iQSS, parameters can be set by unified operation of sensors from different manufacturers from the engineering environment and GOT, thus reducing work time.

Maintenance cost reduction

With iQSS, iQSS-compatible partner sensors can be displayed on a single screen, so you can monitor them closely.

With iQSS, the settings of iQSS-compatible partner sensors can be backed up and restored on the SD memory card of the PLC.

With iQSS, sensor data can be registered as sequencer logging data.

Data management and analysis of sensors without a logging function are possible, improving traceability.

There are many setting items and management is difficult

There are many setting items and management is difficult It is difficult to set each sensor parameter individually

It is difficult to set each sensor parameter individually It takes time to change settings

It takes time to change settings It takes time to spread the system

It takes time to spread the system System configuration management

System configuration management Label programming

Label programming monitoring

monitoring Reading and writing sensor settings

Reading and writing sensor settings

Contact Us

Contact Us Call Center

Call Center