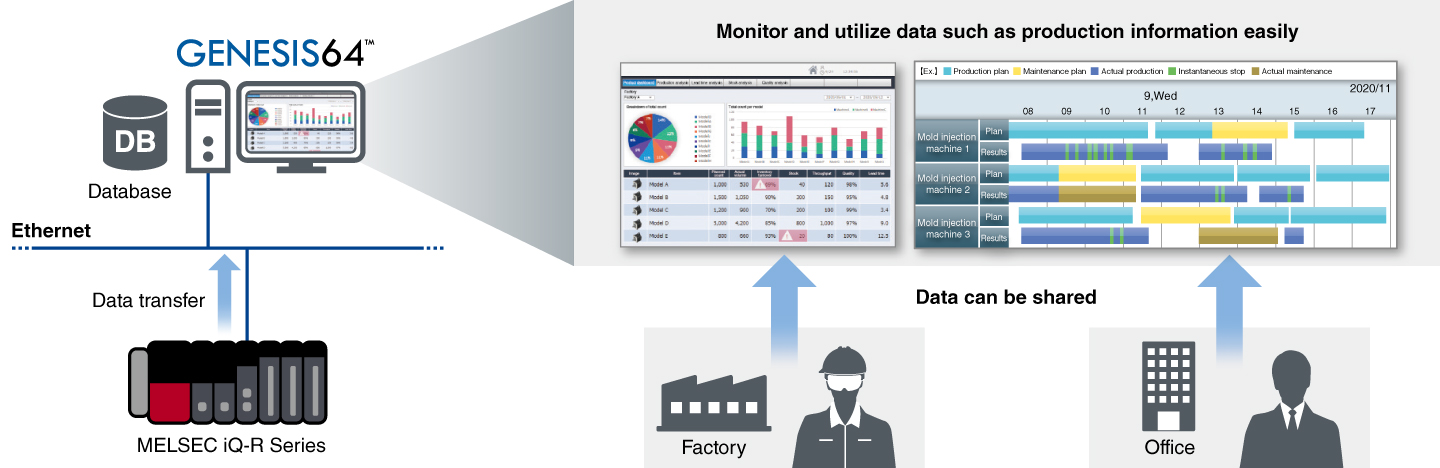

Product Features

MES Interface Module

System configuration costs reduced by 65%*2

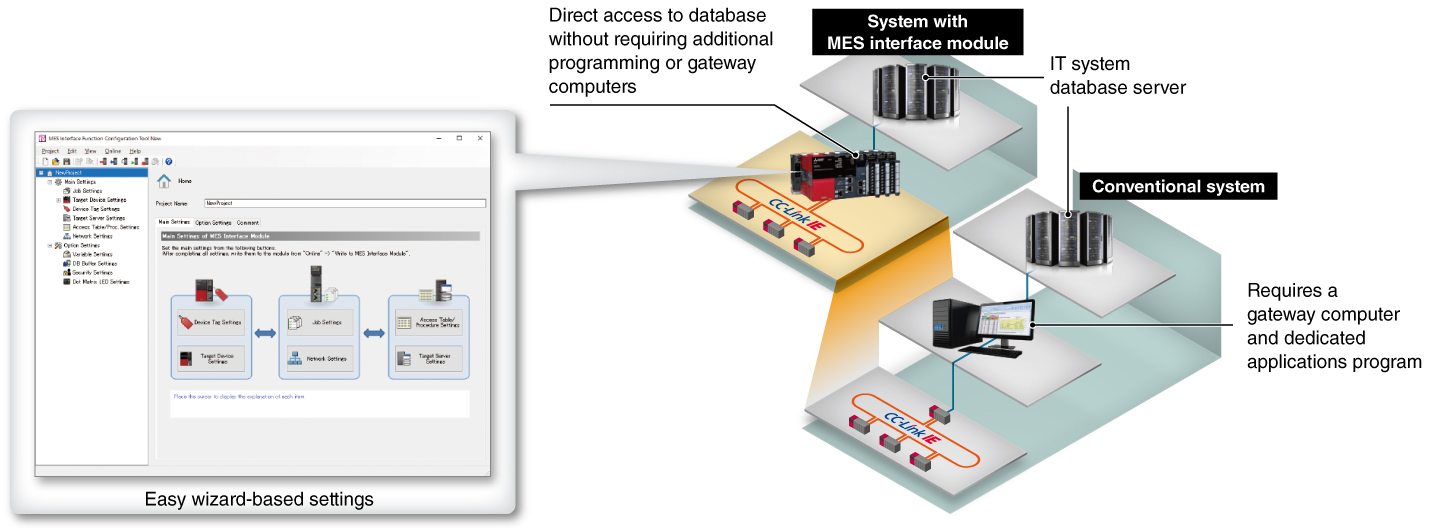

MES interface modules enable direct connectivity between IT database servers and programmable controllers on the shop floor, eliminating the need for gateway computers or specified programs. Being much more reliable than computers, the MES interface modules save on maintenance costs typical of computers.

High-speed and large-capacity data collection

Along with ever-changing manufacturing trends, improving machine productivity and maintaining manufacturing quality through meticulous traceability have become a fundamental part of manufacturing. The MES Interface module addresses these requirements with its high-performance and large-capacity data handling. These features are exceptionally useful in glass and rechargeable battery manufacturing industries.

*4: Comparison of data sets that can be handled in database communication. One project may contain up to 4096 data sets for the MELSEC-Q Series, and 65536 for the MELSEC iQ-R Series.

Intuitive and easy-to-use setup software

The setup of the module can be done easily using its wizard-like configuration tool. SQL sentences can be automatically generated just be setting various parameters in the tool, without having to develop dedicated programs to enable communication with the database server.

MES Interface module specifications

| Item | RD81MES96N |

|---|---|

| Database connection | |

| Supported database*5 | Oracle® Database, Microsoft® SQL Server®, Microsoft® Access®, MySQL®, PostgreSQL |

| SQL text | SELECT, INSERT, UPDATE, DELETE, Multi-SELECT, Multi-INSERT*6, STORED PROCEDURE |

| Database communication action field | 65,536 |

| Accessible CPU module*5 | MELSEC iQ-R, MELSEC-Q, MELSEC-L, MELSEC iQ-F, MELSEC-F Series |

| Data sampling interval | |

| High speed data sampling (ms) | Sequence scan time synchronization, 1...900 (up to 32K points) |

| General data sampling (s) | 0.1...0.9, 1...3600 |

| Function | |

| DB record read/write | Reads/writes data in the database of the host information system |

| Device memory read/write | Reads/writes device memory data of the CPU module |

| Trigger condition monitoring | Monitors values of the time or device tag components etc., and starts jobs when a trigger condition changes from false to true (the condition is satisfied) |

| Data operation and processing | Performs four arithmetic operations, obtains remainder, performs character string operation, etc. |

| Program execution | Executes a program on the server through a MES Interface module |

| DB buffering | Buffers the data sent to the database, and resend it after recovery, when the data cannot be linked due to the disconnection of the network between MES Interface module and the database or failure of the database etc. |

| REST server*7 | Enables job-related operations and job information acquisition from the REST client (Also supports the XML process function for the MELSEC-Q Series MES interface module) |

| Firmware update*5 | ● |

*6: Supported only when used with a SQL Server® database.

*7: REST: Representational state transfer