Product Features

Countless applications are possible

![]()

A variety of control types including positioning control, speed-torque control, synchronous control and electronic cam control can be implemented easily with simple parameter settings and a sequence program.

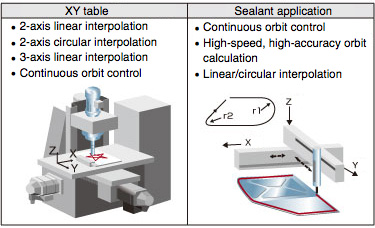

Positioning control

- Support for a multitude of applications thanks to a wide variety of control formats including linear interpolation control (up to 4 axes), 2-axis circular interpolation control, fixed feed control and continuous orbit control.

- Use a sequence program to set the positioning address, speed, etc. for easy automatic operation.

- Quickly implement powerful auxiliary functions such as step operation, target position change, M codes, and the skip function.

Speed-torque control

- Tension control applications such as winding and rewinding are supported.

- Switch from positioning control, to speed-torque control, and back to positioning control.

Because the present location is tracked even in speed- torque control mode, it is possible to maintain the current absolute position when returning to positioning control.

Synchronous control and electronic cam control

- Electronic cam control may be used alone or combined with synchronous control.

Example application for electronic cam control:

To create a movement path around a workpiece using positioning control, axis 2 waits for axis 1 to complete the move from P1 to P2 before it begins moving from P2 to P3. By using electronic cam control, axis 2 does not need to wait for axis 1 to complete its movement and the in position time can be shortened.

Many functions in a compact design

![]()

Use a synchronous encoder with synchronous control

- Input pulses from a synchronous encoder can be used to perform synchronous control and electronic cam control.

- The incremental synchronous encoder can be used by using the LD77MS built-in interface. An option unit is not required.

- To further improve the synchronization accuracy, the phase compensation function, designed to compensate for synchronous encoder delays, can be used.

Standard mark detection function

- The built-in mark detection signal interface allows these units to be used in packaging systems for example, without additional option modules.

Automatic cam data generation for rotary cutter

- Complicated cam data for rotary cutters can be automatically generated just by specifying a few parameters like the sheet length and synchronization width.

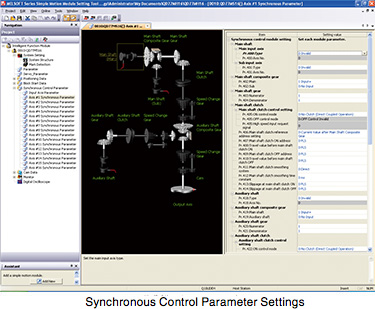

Perfect synchronous control is easy to achieve

![]()

Replace mechanical gears, shafts, speed change gears, cams, etc. and generate synchronous control operations using software.

- Complicated programs are unnecessary for synchronous control because it can be implemented easily using parameter settings.

- Start and stop synchronous control for each axis.

Use the synchronous control axis and positioning control axis together. - Convey the travel value of main shaft to the output axis via the clutch.

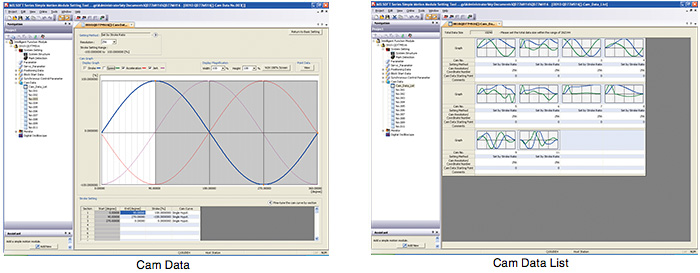

Cam control made simple

![]()

Create cam data patterns easily.

- Create cam profiles unrestricted by existing concepts of electronic cam control.

- Change the acceleration, speed, stroke, and jerk while simultaneously seeing how it effects the profile.

- Easily check created cam data by viewing them as thumbnails.

- Import and export cam data in CSV format.

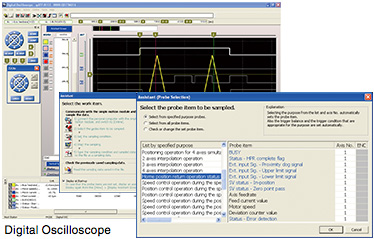

Simplified debugging and commissioning

![]()

Digital oscilloscope function

- Collection of data from the simple motion module is synchronized with the operation cycle and waveform displays to facilitate an efficient start up.

- The assistant function explains each step.

- Use the purpose-based probe setting to easily set frequentlyviewed data.

- Sample 16CH word and 16CH bit data and display 8CH words and 8CH bits in real time.

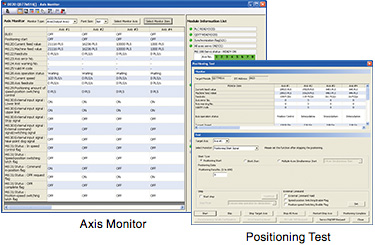

Monitor and test functions

- Complete the system installation and perform operational checks easily using powerful monitor and test functions.

- Select items to be displayed on the monitor using a wealth of information monitoring options.

- The test function can be used to check basic operations without a sequence program.