Product Features

Four types of tension control

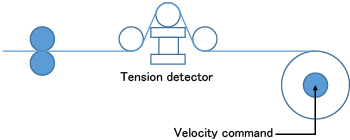

Tension sensor feedback velocity control This converting library executes the PID control according to the value detected by the tension detector and controls the velocity so that the tension reaches the specified tension.

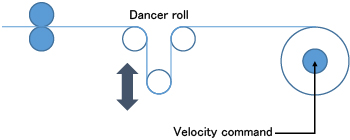

| Dancer feedback velocity control This converting library detects the position of the dancer roll and controls the velocity to reach the target position.

|

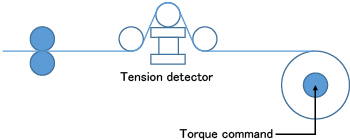

Tension sensor feedback torque control This converting library performs the PID control according to the value detected by the tension detector and controls the torque so that the torque reaches the set tension value.

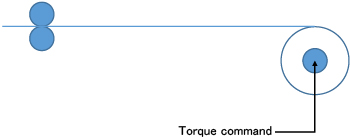

| Tension sensorless torque control This converting library performs the torque control without sensors to control the tension in unwinding and rewinding.

|

Additional functions

The tension gain in tension sensor feedback control and dancer feedback control is automatically tuned.

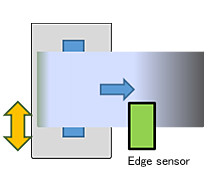

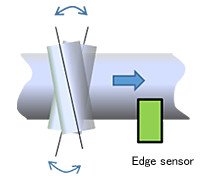

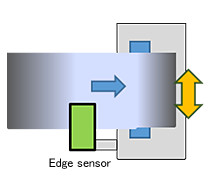

Edge position control

Edge position of the material is detected and corrected.

- ●When the unwinder axis moves

(The edge sensor position is fixed.)

- ●When the intermediate axis moves

- ●When the rewinder axis moves

(The edge sensor follows the rewinder axis.)

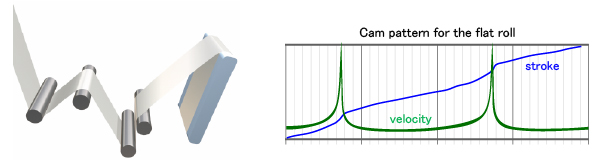

Cam generation for flat roll

Flat type rewinder generates a velocity pattern (cam pattern) so that the feed speed of the material becomes constant, suppressing tension fluctuation for winding operation.