Product Features

Downtime reduction

When a fault occurs, AI analysis and other diagnosis functions solve the problem quickly.

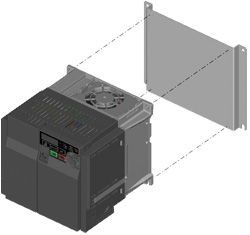

Streamlining the installation process

Streamlining the installation process

- Compatible installation size

The installation size was determined to assure exchangeability with the FR-E700 series. Installation interchange attachment options are available for facilitating replacement with the models of different size.

(The depth required for installation increases by 12 mm.)

Quick reaction to troubles

Quick reaction to troubles

- Power supply from USB port

With the power supplied from the computer (USB bus power connection)*1, parameters can be set using FR Configurator2 while the main circuit power supply is OFF.

Maintenance can be performed quickly and safely.

- *1: The maximum SCCR should be 500 mA. A PU connector cannot be used during USB bus power connection.

Easy and fast wiring

Easy and fast wiring

- Control circuit terminal

- Spring clamp terminals have been adopted for control circuit terminals for easy wiring.

Furthermore, wires can be protected against loosening or contact faults due to vibrations during operation on a bogie or during transport. No additional screw tightening is required. - The removable control circuit terminal block facilitates replacement with a new one.

| FR-E800 | FR-E800-E | FR-E800-SCE | ||

|---|---|---|---|---|

| Input terminal | 7 | 2 | 0 | |

| Output terminal | Open collector | 2 | 0 | 0 |

| Relay | 1 | 1 | 1 | |

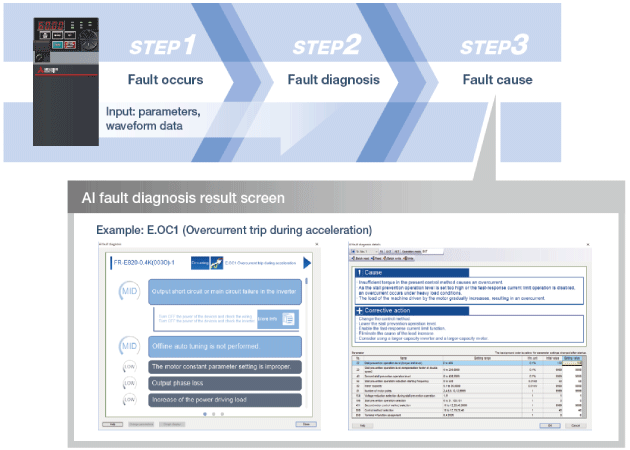

Troubleshooting supported by AI technology

Troubleshooting supported by AI technology

- AI fault diagnosis

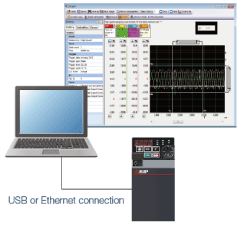

The inverter is connected to the engineering software FR Configurator2 (USB/Ethernet connection).

Maisart*2 (Mitsubishi Electric's AI technology) is integrated in the software to analyze data and help identify the cause of a fault*3 (this function is enabled during speed control).

This function enables the fastest troubleshooting procedure without requiring any special skills, which contributes to downtime reduction.

- *2: Maisart is Mitsubishi Electric's brand of AI technology. The name stands for "Mitsubishi Electric's AI creates the State-of-the-ART in technology". This means that it is using our proprietary AI technology to make everything smarter.

- *3Diagnosable faults: Overcurrent trip and overvoltage trip (other faults will be supported in the future.)

Trouble analysis from a remote location

Trouble analysis from a remote location

- Trace function

Users can read the data file in FR Configurator2 for graph display or send it by e-mail to someone away from the worksite, which facilitates the trouble analysis.

- Clock function

It is possible to synchronize the internal clocks of the devices that comprise the CC-Link IE TSN communication.

- *4: The clock does not run while the control circuit power is OFF. The clock needs to be set every time after turning ON the inverter power.

By using the real-time clock function with the optional LCD operation panel (FR-LU08) (when using battery), the clock keeps running even when the control power supply is turned OFF.