Product Features

Safety controller MELSEC-WS Series

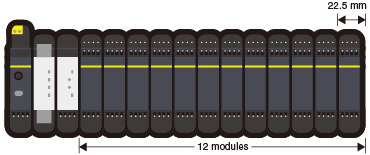

This compact safety controller complies with EN ISO 13849-1 Category 4/PL e and IEC 61508 SIL 3 safety standards. It is ideal for small- to medium-scale safety control system. Safety I/O points can be extended to 144 points per CPU module according to the system configuration. Utilizing the dedicated Setting and Monitoring Tool*1, setup and logic creation can be easily done.

System configuration

*3. No. of input points: 8 points (single wiring)

*4. Safety relay output: 4 points

Safety control can be easily added to existing programmable controllers (CC-Link/Ethernet)

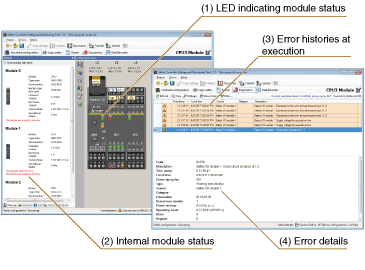

Connecting the safety controller to CC-Link, safety control can be performed with the existing MELSEC iQ-R/Q/L Series module. Furthermore, operation status and error status of the safety controller can be monitored with the programmable controller. This helps quickly identifying the factor of emergency stop and faulty equipment.

Flexible extensibility

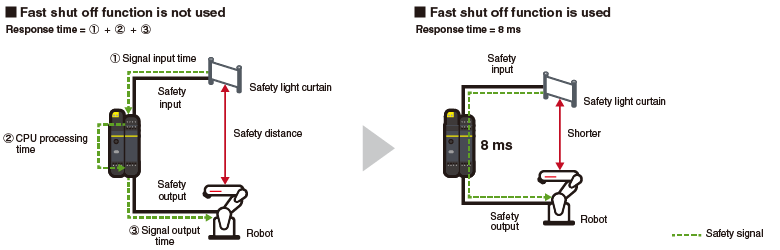

Fast shut off function realizes a response time of 8 ms

Fast shut off function that enables the safety I/O module to shut off safety output without going through the CPU module realizes a response time of 8 ms. Since similar response time is achieved even with increased I/O points, the safety distance can be shortened even in the large-scale safety system.

Flexi Line/Flexi Link

Safety communication network between safety controllers

Safety communications between safety controllers can be easily established at a low cost just by connecting the CPU modules with dedicated cables. Safety communication is realized without a dedicated network module, allowing utilization in various production site. In addition, coordination between multiple devices is possible, improving production system safety.

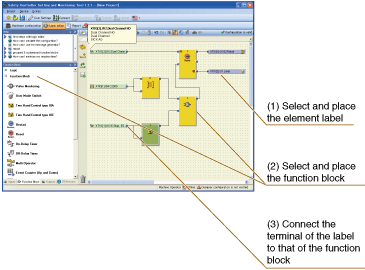

Dedicated “Setting and Monitoring Tool*6” provides intuitive system configuration environment

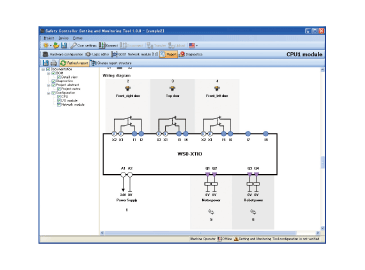

Hardware configuration can be easily and quickly done using a wide range of elements*7.

- *6. For details on how to obtain the tool, please contact your local Mitsubishi Electric sales office or representative.

- *7. Connecting parameters of major safety equipment, such as emergency stop switches, safety door switches and safety light curtains, are expressed by an icon. Make settings simply by drag-and-drop decision. Elements for Safety devices of Mitsubishi’s partners are also available. Please contact your local Mitsubishi representative.

ON/OFF status of safety input signal and safety output signal processed by the safety controller can be stored.*8 Results recorded on the Setting and Monitoring Tool can also be viewed on the computer to utilize for troubleshooting.

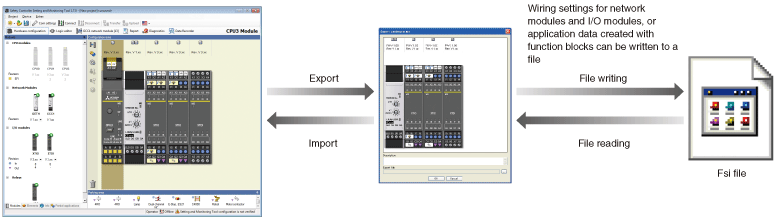

The connection settings to the I/O modules or application logic created with function blocks can be stored in a single setting file, and data can be read out of stored setting files.

Lineup

| Item | Model | Abbreviated product model name |

|---|---|---|

| CPU | WS0-CPU000200 | WS0-CPU0 |

| CPU (with EFI) | WS0-CPU130202 | WS0-CPU1 |

| CPU (with EFI, Flexi Line) | WS0-CPU320202 | WS0-CPU3 |

| Memory plug for CPU (for WS0-CPU0/WS0-CPU1) | WS0-MPL000201 | WS0-MPL0 |

| Memory plug for CPU (for WS0-CPU3) | WS0-MPL100201 | WS0-MPL1 |

| Safety input | WS0-XTDI80202 | WS0-XTDI |

| Safety I/O combined | WS0-XTIO84202 | WS0-XTIO |

| Safety relay output | WS0-4RO4002 | WS0-4RO |

| USB/RS-232 conversion cable | WS0-C20M8U, WS0-UC-232A | – |

| RS-232 cable connecting to CPU | WS0-C20R2 | – |

| CC-Link interface | WS0-GCC100202 | WS0-GCC1 |

| Ethernet interface | WS0-GETH00200 | WS0-GETH |

| Screw-in replacement terminal block | WS0-TBS4 | – |

| Spring clamp replacement terminal block | WS0-TBC4 | – |

| Setting and Monitoring Tool | SW1DNN-WS0ADR-B | – |