Product Features

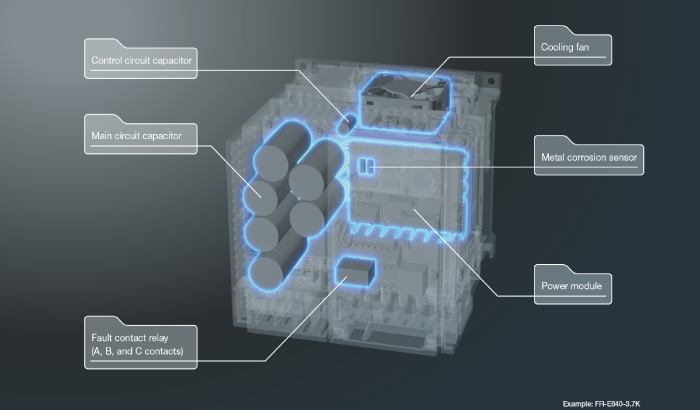

Improved maintainability

and preventive maintenance support stable system operation.

Real-time monitoring for early fault detection

Real-time monitoring for early fault detection

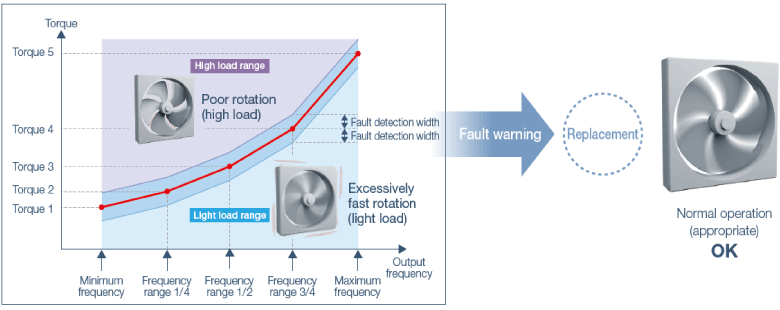

- Load characteristics fault detection function

When a mechanical fault such as clogging of the filter occurs, the inverter outputs a warning or shuts off the output to prevent system damage.

The speed–torque characteristic is stored while no fault occurs, enabling comparison between the measured data and the stored data.

Supporting scheduled maintenance planning

Supporting scheduled maintenance planning

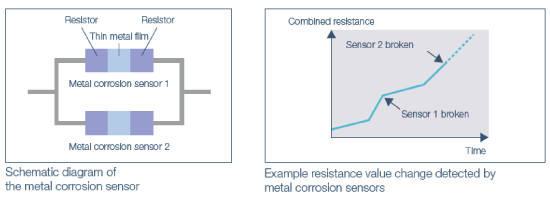

- Environmental impact diagnosis function

The world's first*1 “Corrosive-Attack-Level Alert System (CALAS™)”*2 makes it possible to identify signs of inverter damage caused by corrosive gas such as hydrogen sulfide*3. This function notifies operators when factors such as the production environment need to be improved, resulting in reduction in the equipment downtime (for coated models (-60/-06) only).

The combined resistance of multiple metal corrosion sensors is measured to detect the level of degree of metal part corrosion caused by corrosive gas in the air.

- *1:According to our investigation as of September 10, 2019.

- *2:Patent applied for.

Alert system for the risk of corrosive damage (degree of corrosion) of electrical equipment - *3:Others will be supported in future.

- *5:Terminals A, B, and C of the inverter

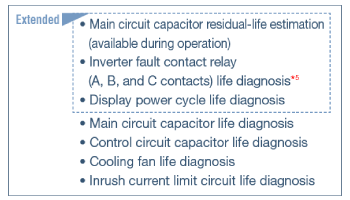

- Enhanced life diagnosis function

Availability of life diagnosis checks is extended as compared to the FR-E700 series. This enhanced diagnosis function ensures reliable operation of the system.

The design life of cooling fans and capacitors has been extended to 10 years*4.

- *4:Surrounding air temperature: annual average 40°C (free from corrosive gas, flammable gas, oil mist, dust and dirt)

Output current: 80% of the inverter ND rating

Since the design life is a calculated value, it is not a guaranteed value.

Supporting preventive maintenance of peripherals

Supporting preventive maintenance of peripherals

- Maintenance timer

The Maintenance timer signal is output when the inverter's cumulative energization time reaches the time period set with the parameter. This can be used as a guide for when the maintenance of the equipment should be conducted.

Thorough customer support

Thorough customer support

- FA Center network

Our global network offers reliable technical support and customer satisfaction.

- Setup information web page

Our setup information web page provides easy access to manuals, videos, and outline dimension drawings.