Product Features

Advanced positioning function

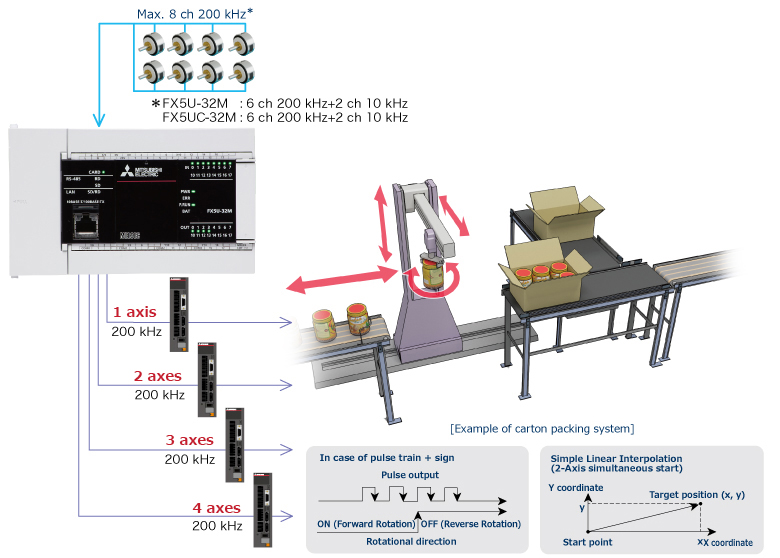

Built-in Positioning (200 kpps, 4 axes built in) + Positioning 2 axes (200 kpps, 2 axes)

Positioning capable of 20 μs high-speed start

FX5U/FX5UC is equipped with built-in positioning functions that can utilize 8ch high speed counter function and 4 axes pulse output. In addition to the existing interrupt stop operation and variable speed operation, new functions have been added and made even easier to use. Furthermore, up to four high-speed pulse I/O modules can be connected for affordable multi-axis control.

High-speed pulse I/O module (Positioning function (2 axes))

Positioning function (2 axes) built in

The high speed pulse I/O module is an I/O module with positioning functions and high speed counter functions added.

Realize 6 axis control by expanding FX5U/FX5UC.

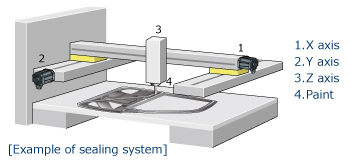

System conguration example (positioning function)

Simple Motion Module (4-axis control module)

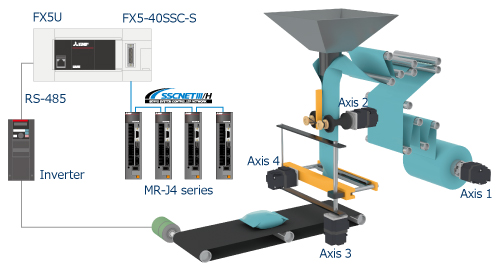

Positioning Control with SSCNET III/H

FX5-40SSC-S is equipped with a 4-axis positioning function compatible with SSCNET III/H.

By combining linear interpolation, 2-axis circular interpolation and continuous trajectory control in the program set with a table, a smooth trajectory can be easily drawn.

| Main functions | Application examples |

|---|---|

|

|

Advanced Motion Control

Making Simple Motion with compactly packed extra functions

By starting with parameter settings and the sequence program, the Simple Motion modules can realize a variety of motion control including positioning control, advanced synchronous control, cam control and speed-torque control.

- Use synchronous control and cam control to build a system perfect for your equipment.

- Register up to 64 types of cam patterns to respond to any type of packaging needs.

- Perform continuous operation without stopping the workpiece operation.

Synchronous control

In addition to synchronous control that replaces physical machine mechanisms such as gears, shaft, transmission and cam with software, functions such as cam control, clutch and cam auto-generation are easily realized. Since synchronous control can be started and stopped for each axis, programs can contain both synchronous control axes and positioning control axes. Up to four axes can be synchronized to the synchronous encoder axis, enabling use with a variety of systems.

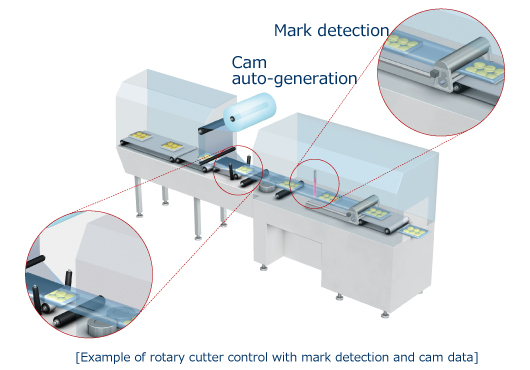

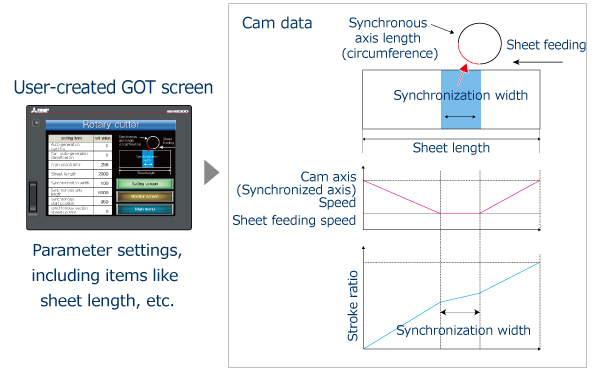

Cam data auto-generation

Easily program and automatically generate difficult cam data for rotary cutters just by inputting the sheet length, synchronization width, and cam resolution, etc.

Mark detection function

The cutter axis deviation can be compensated by detecting a mark on the workpiece so the workpiece can be cut at a constant position.